MX3D just officially unveiled the world's first 3D-printed stainless steel bridge. Designed by Joris Laarman Lab, it is made of a completely new type of steel, an 12,5 metre-long bridge, and will be installed in De Wallen, the largest and best-known red-light district in the center of Amsterdam, to cross one of the oldest and most famous canals the Oudezijds Achterburgwal.

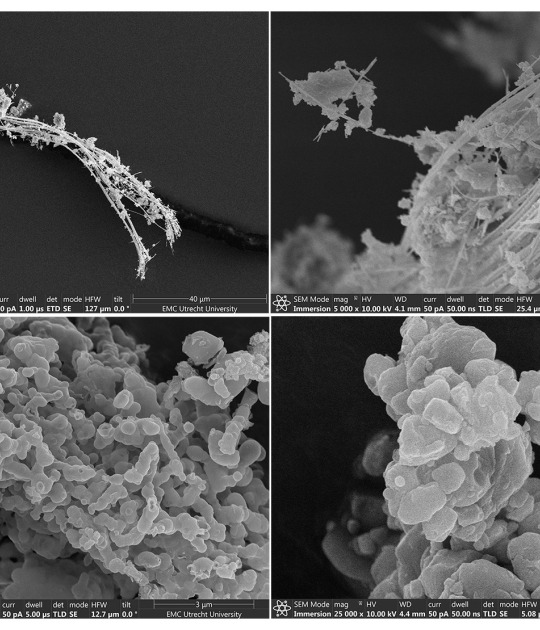

The project has reached a major milestone with the 3D robotically printed span of the bridge complete and revealed to the public. It took four robots, nearly 4,500 kilograms of stainless steel, about 1,100 kilometer of wire, and six months of printing to build the sinuous, undulating structure, with a rough surface, which looks like it’s straight out of a science-fiction movie.

In 2015, Laarman and the team partnered various companies and organisations, namely Joris Laarman Lab, Arup is the lead structural engineer, ArcelorMittal provides the metallurgical expertise, Autodesk assists with their knowledge on digital production tools, Heijmans is their construction expert, Lenovo supports them with computational hardware, ABB is the robotics specialist, Air Liquide & Oerlikon know everything about welding and lastly, Plymovent protects the air our employees breath whilst AMS and TU Delft do invaluable research. Gemeente Amsterdam is the first customer of their collaborative bridge building department.

The newly printed bridge just arrived back in MX3D's workshop in north Amsterdam from a larger facility outside the city. There, the team of designers and engineers that has been working on the project for years will test the bridge's integrity and add some finishing touches, including a clear coat to protect the ruddy steel exterior from the elements and a steel deck - which is basically just a huge plate of traditional steel - that will serve as a walkway. The final phase will include the installation of a series of smart sensors that will monitor the bridge's health and take a slew of measurements in real-time, including air quality and weight dispersion so the bridge will actually know how many people are walking on it and how quickly they're moving. The sensor data will also be fed to a "digital twin" bridge model that will help engineers understand how the bridge is performing over time and make tweaks to future designs accordingly.

Scientists from the Steel Structures Research Group at Imperial College London had led on the research to undertake structural testing on the 3D printed steel.

Commenting on the successful testing, Professor Leroy Gardner said:

“In the absence of structural design provisions for 3D printed steel, physical testing is an important part of ensuring the safety of the structure. The recent testing confirmed not only that the bridge could withstand the applied load, but also that the numerical simulation of the bridge developed by the Steel Structures Research Group provided an accurate representation of the behaviour observed in practice.”

Safety is a key part of all of these tests and the sensor network that will follow. Given the fact that a 3D-printed bridge like this has never existed, MX3D worked with the city to establish a unique, new safety standard as well as a testing plan to ensure the bridge's lasting integrity. The sensor network will also enable engineers to monitor and address safety issues with such accuracy that the 3D-printed might well be the safest bridge in the city.

The genesis of the 3D-printed bridge was unconventional. In 2004, Joris Laarman founded a design lab in Amsterdam and began experimenting with various materials and applications for various technologies. Much of Laarman's work looked to natural designs for inspiration, but a growing interest in technology led to the development of a six-axis robot that could do large-scale, free-form 3D printing and the founding of MX3D. Whereas traditional 3D-printing takes place inside of a machine, this new type of technology can print in outside, without conventional limitations.