Cave Urban reimagined this typology by once again using sustainable local materials, recovering a culturally rooted element, and developing it through collaboration with local actors and leaders to facilitate public activities, demonstrating Bali’s capacity to lead regenerative construction practices.

The building is the first in Bali to use structural laminated bamboo. A life cycle analysis determined the building’s negative carbon footprint at -2062 kgCO₂e for Stage A emissions, representing a 104% reduction compared to an equivalent structure built with high-carbon-content materials.

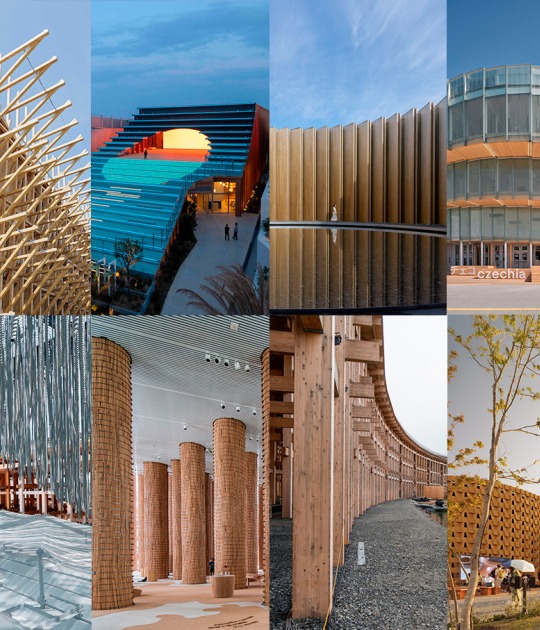

The Bale Bio pavilion by Cave Urban. Photograph by Iwan Sastrawan.

Project description by Cave Urban

BaleBio is an 84m² pavilion in Bali, Indonesia, that demonstrates the potential of regenerative architecture. Located at Mertasari Beach in Sanur, Bali. The BaleBio was designed through a process of consultation with local partners and the community to establish a brief for the project and culturally relevant building typologies.

Developed as part of the Bauhaus Earth Rebuilt Initiative, the pavilion serves both as a community space and as a prototype for architecture that restores ecosystems, supports local economies, and re-establishes connections between cultural heritage and contemporary construction methods.

Inspired by the Bale Banjar: A traditional open-air meeting hall central to Balinese village life.

Once made of timber and local materials, these communal structures are being replaced with concrete structures. Reimagining this typology in local sustainable materials offered a culturally grounded way to initiate conversations on regenerative design.

The BaleBio was developed through collaboration with local stakeholders and champions to accommodate various public activities, showcasing Bali’s capability to lead in regenerative building practices.

Material Selection

The BaleBio Pavilion was designed as a low-impact, regenerative structure, focusing on reducing resource use and construction waste at every stage—from design to disassembly.

Construction combined traditional craftsmanship with engineered precision. Prefabricated laminate bamboo components were manufactured off-site and assembled on-site, with local artisans contributing to the detailing and finishing.

This hybrid approach integrates modern structural techniques with the preservation of local artisanal craft. The design of the BaleBio sought to demonstrate how architecture can have positive social, ecological and economic benefits.

As the first building in Bali to use structural laminate bamboo, the project demonstrated how multiple Sustainable Development Goals can be implemented through regenerative construction.

A life cycle assessment established the building's carbon negative footprint of -2,062 kgCO2e for Stage A emissions. This demonstrated a 104% reduction in emissions when compared to an equivalent structure built from carbon-intensive materials.