The proposal by Civic Architects & VDNDP was conceived as an exhibition building that would make academic and research activities visible. Its formal organization is based on the metal and welding workshop, located 1.4 meters below ground level, which allows for a panoramic view of the space and the machinery from the outside.

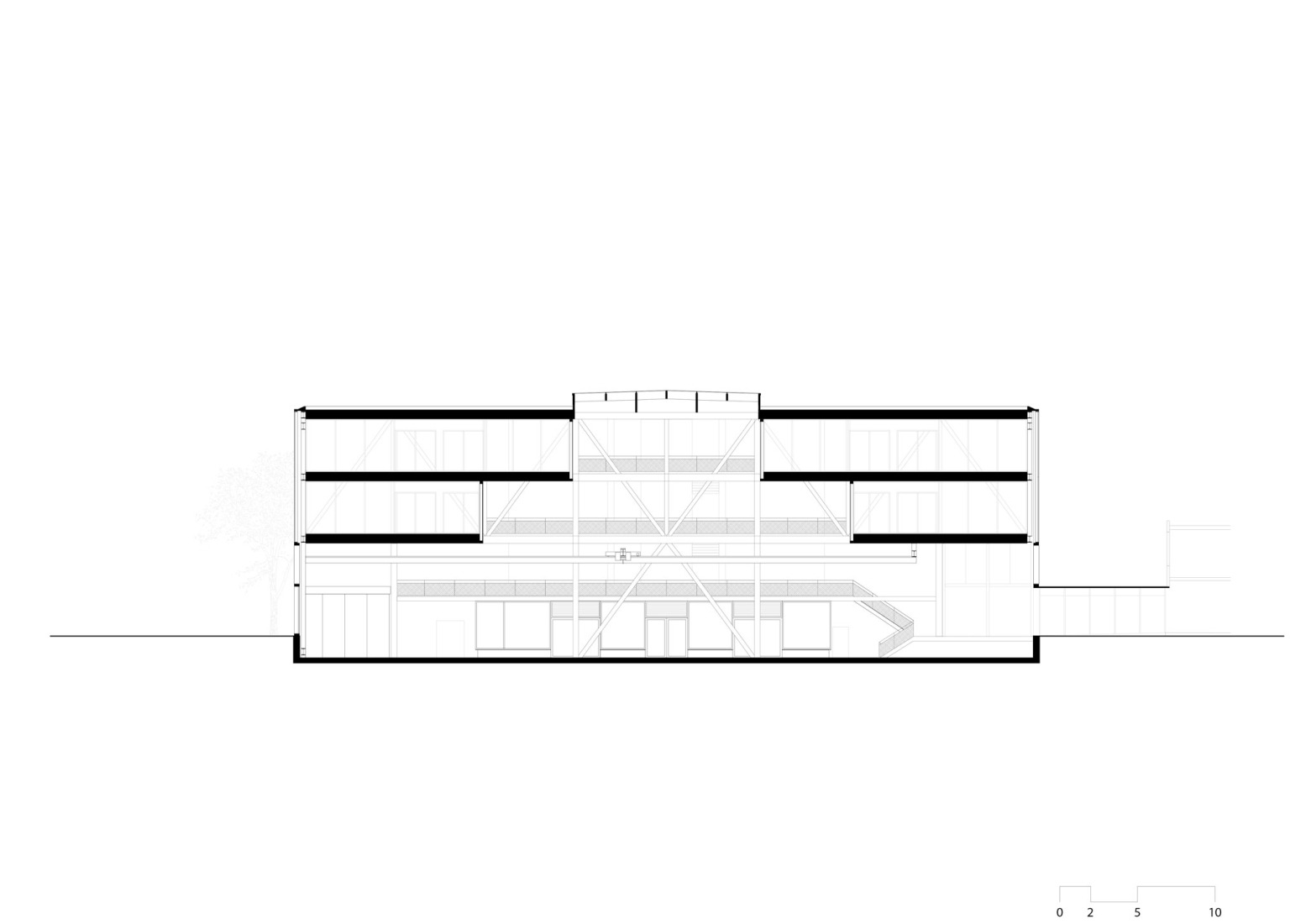

Through a large void, the different levels are visually connected; a pyramidal atrium introduces natural light and vertically links the processes where prototypes are developed and classes take place, displaying them as if in a showcase. The compact layout stacks five workshops, laboratories, and measuring spaces, fostering interaction and visual contact among users. Externally, the linear volume integrates into the modern ensemble of the Horst, reinterpreting its service towers through three CLT cores, and balancing openings and enclosures according to the incidence of natural light.

Structurally, the building is composed of two main bays, each measuring 14 meters, and a narrower bay for services. Large two-story steel trusses reduce columns and reinforce the architectural expressiveness, while the CLT cores provide stability. The materials emphasise the technological character: exposed trusses coated in fire-resistant blue, grey floors, and recycled PET ceilings generate a neutral atmosphere, contrasted by larch carpentry that adds warmth. The façade combines wood, glass, and steel, making the internal organization legible and presenting technology as the essence of the project.

Cube by Civic Architects & VDNDP. Photograph by Stijn Bollaert.

Project description by Civic Architects

Expo for ET: sunken workshop floor as the heart of the building

At the Faculty of Engineering Technology (ET), students are trained to design technology that can change the world. That meaning is hardly visible in the current faculty building, “the Horst.” CUBE changes this. Here, you can experience what the faculty stands for.

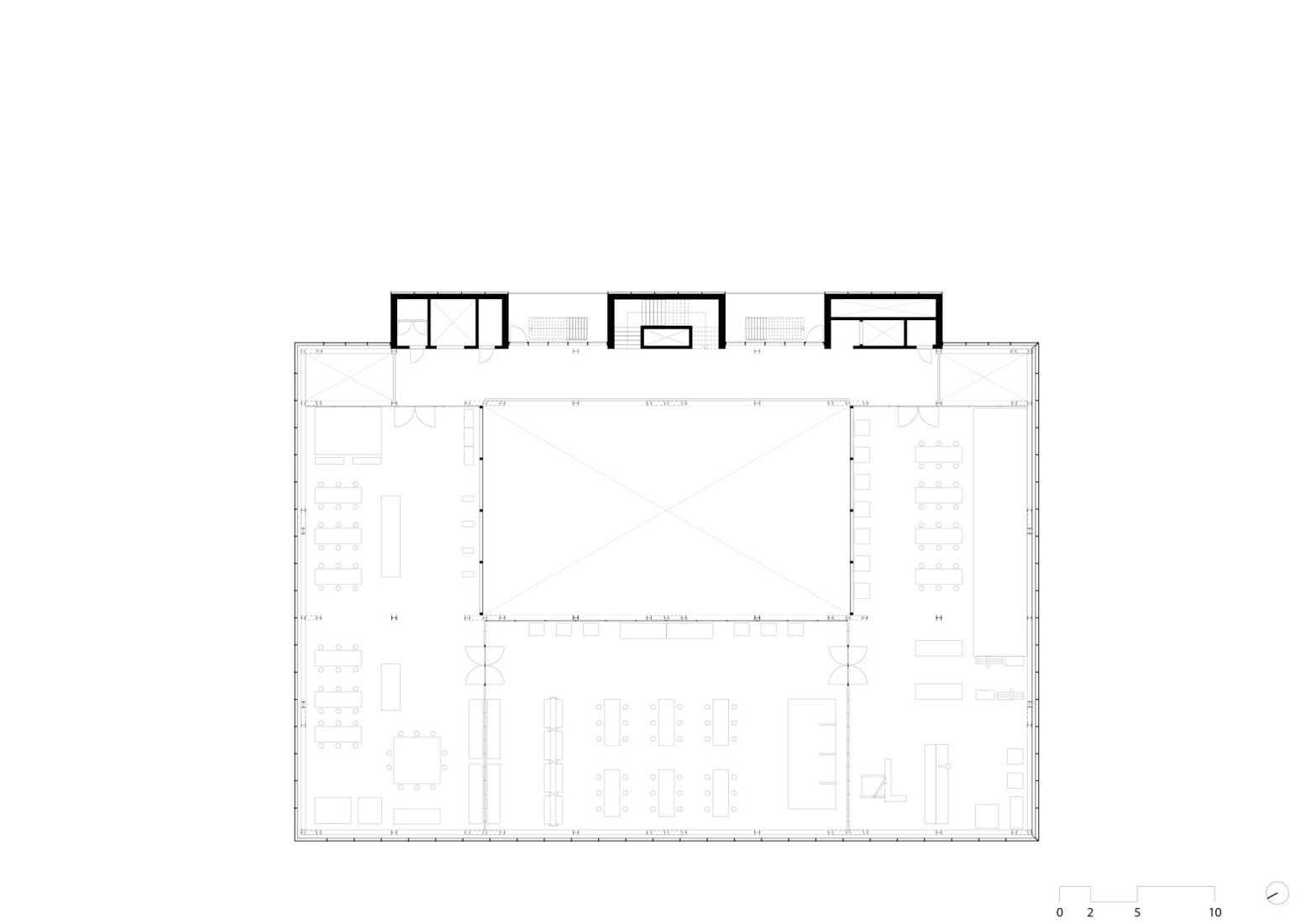

On entering, you overlook the seven-meter-high metal and welding workshop. Because the floor is sunk 1.4 meters below ground level, you see across the machines and have an overview of the entire space. Through a large void, the upper workshops are also visible. Below, students and researchers work with machines; above, prototypes are built and teaching takes place, while the campus landscape is visible outside. In this way, CUBE functions as an expo for the faculty.

Functionality and interaction

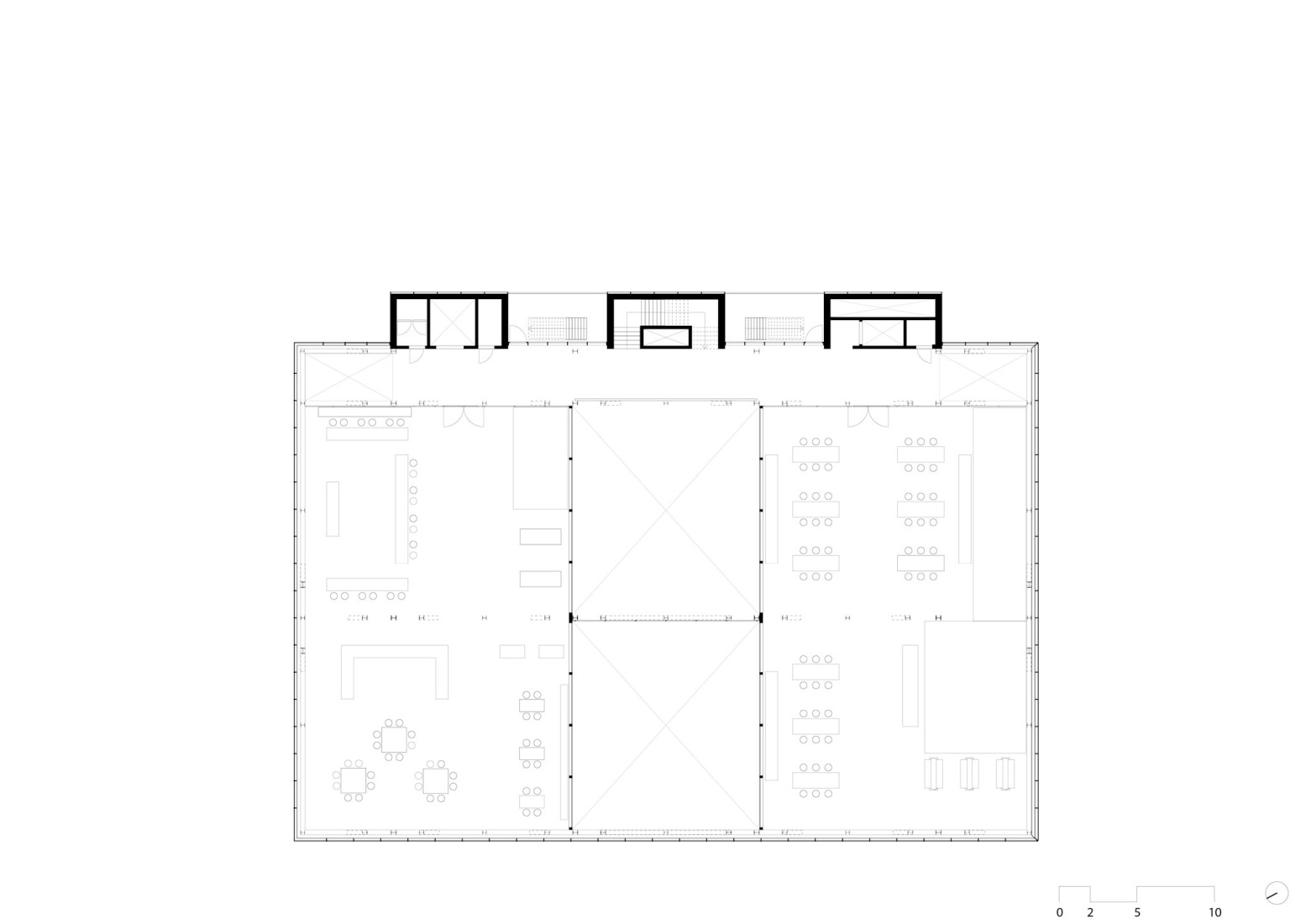

Where research once demanded isolation, innovation today revolves around collaboration. CUBE responds to this by combining functionality and interaction. The building contains five workshops—for welding, metalworking, model building, and assembly—plus around 500 m² of laboratory and measuring spaces. These are stacked rather than side by side, keeping the footprint compact, circulation short, and visual contact between spaces optimal.

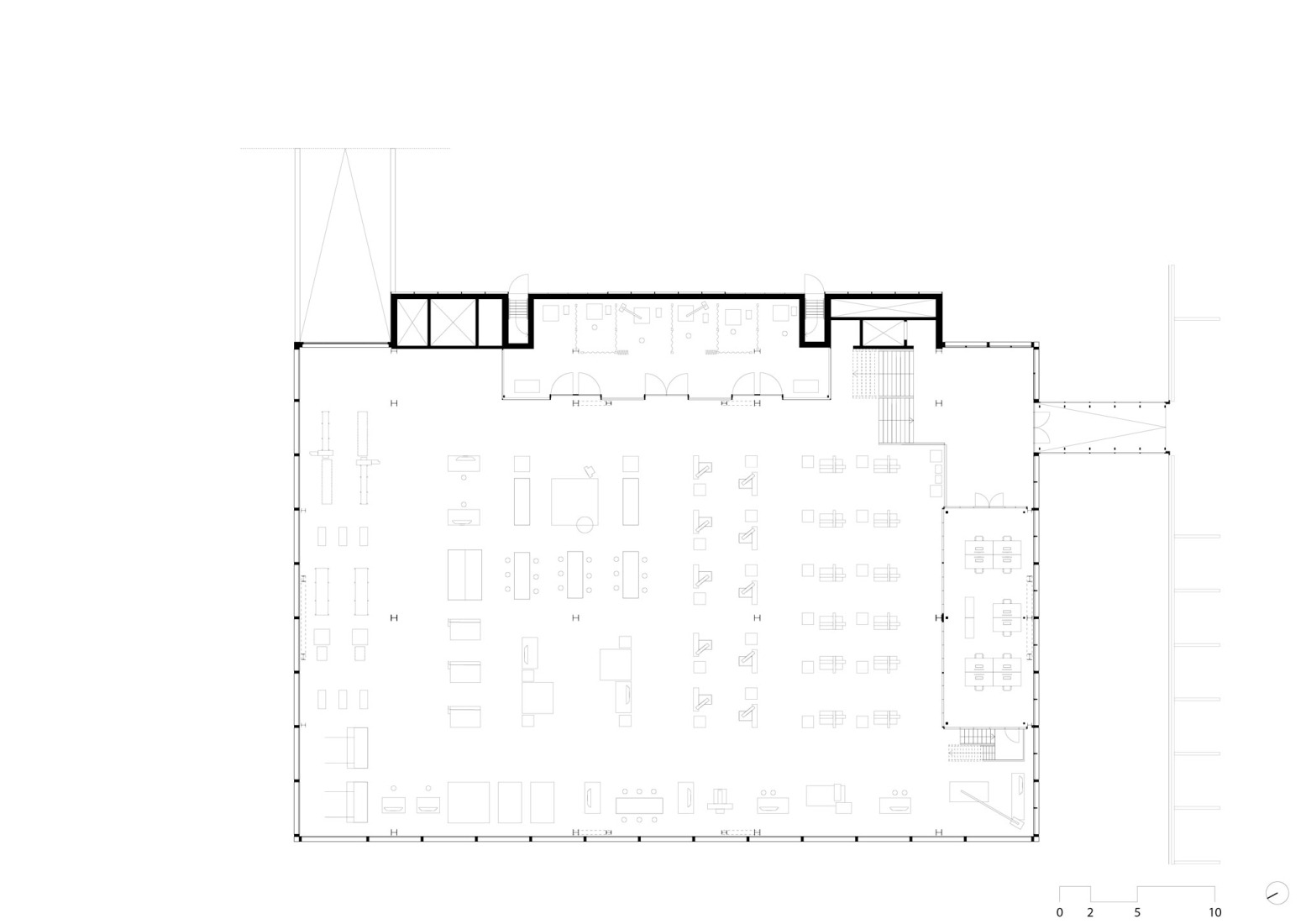

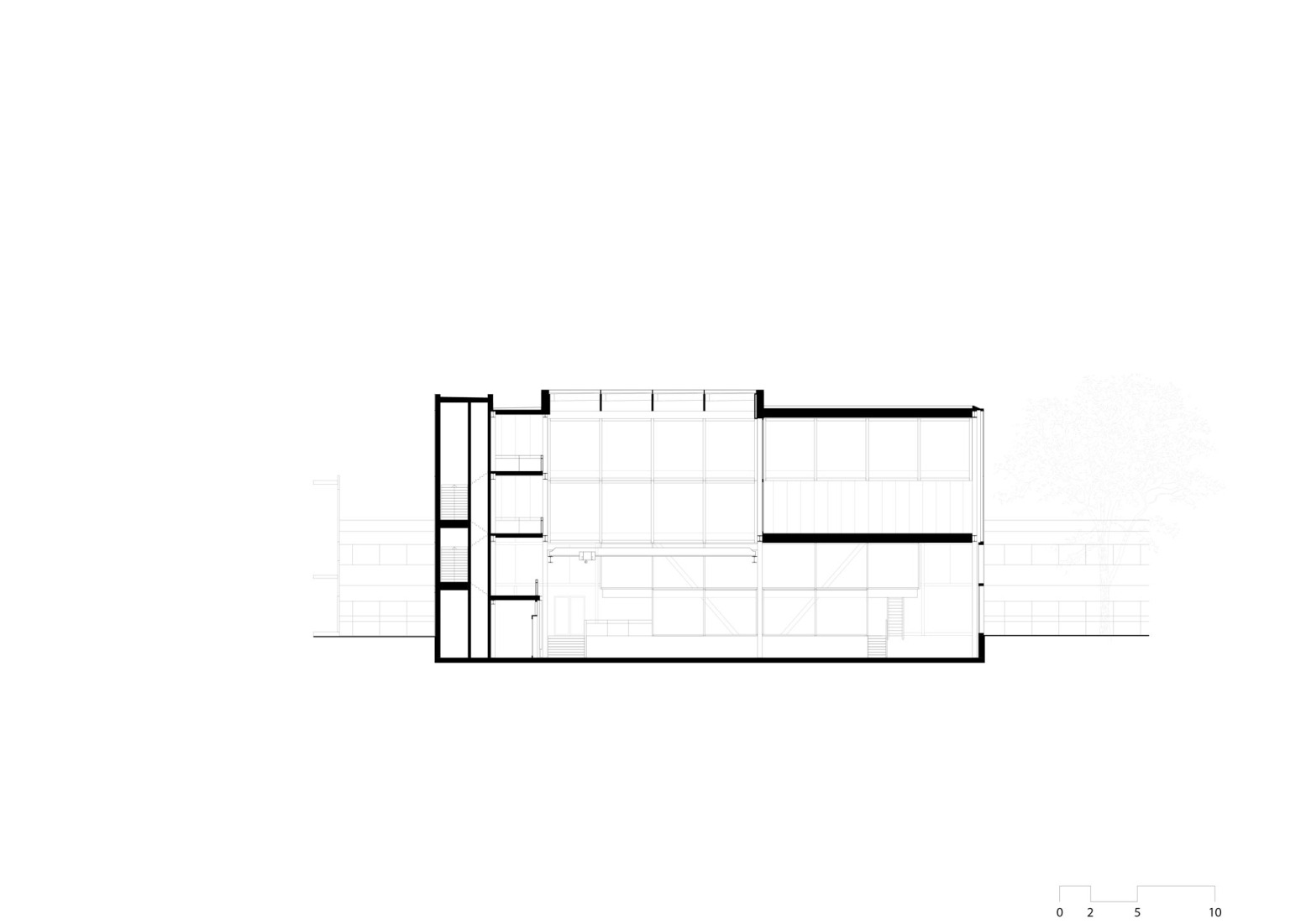

The metal workshop is located in the sunken ground floor. Offices border the south side, slightly raised for oversight. Above are three levels housing air-handling units. The welding workshops are to the right, and the logistics entrance with access for trucks and forklifts lies on the north side. On the second floor are assembly and model workshops, on the third the laboratory rooms.

Circulation spaces, service cores, and storage are placed at the eastern edge as a “backbone” feeding the freely configurable workshops. From here, there is visibility into the large open spaces. A pyramid-shaped atrium brings in generous daylight and visually connects the floors. Work processes are visible everywhere, as if looking under the hood of the faculty.

Structure as architectural statement

The faculty wants the building to be adaptable each semester. Large spans and high load-bearing floors make this possible. The structure consists of two main bays with 14-meter spans and a narrower bay for the backbone. Steel trusses spanning two stories reduce the number of columns in the workshop. The façade triangles and CLT cores containing elevators, stairs, and services provide stability and give the building a distinctive appearance. Thus, the structure offers both a rational solution for flexible use and a pronounced architectural gesture fitting for the faculty.

Machine in the landscape

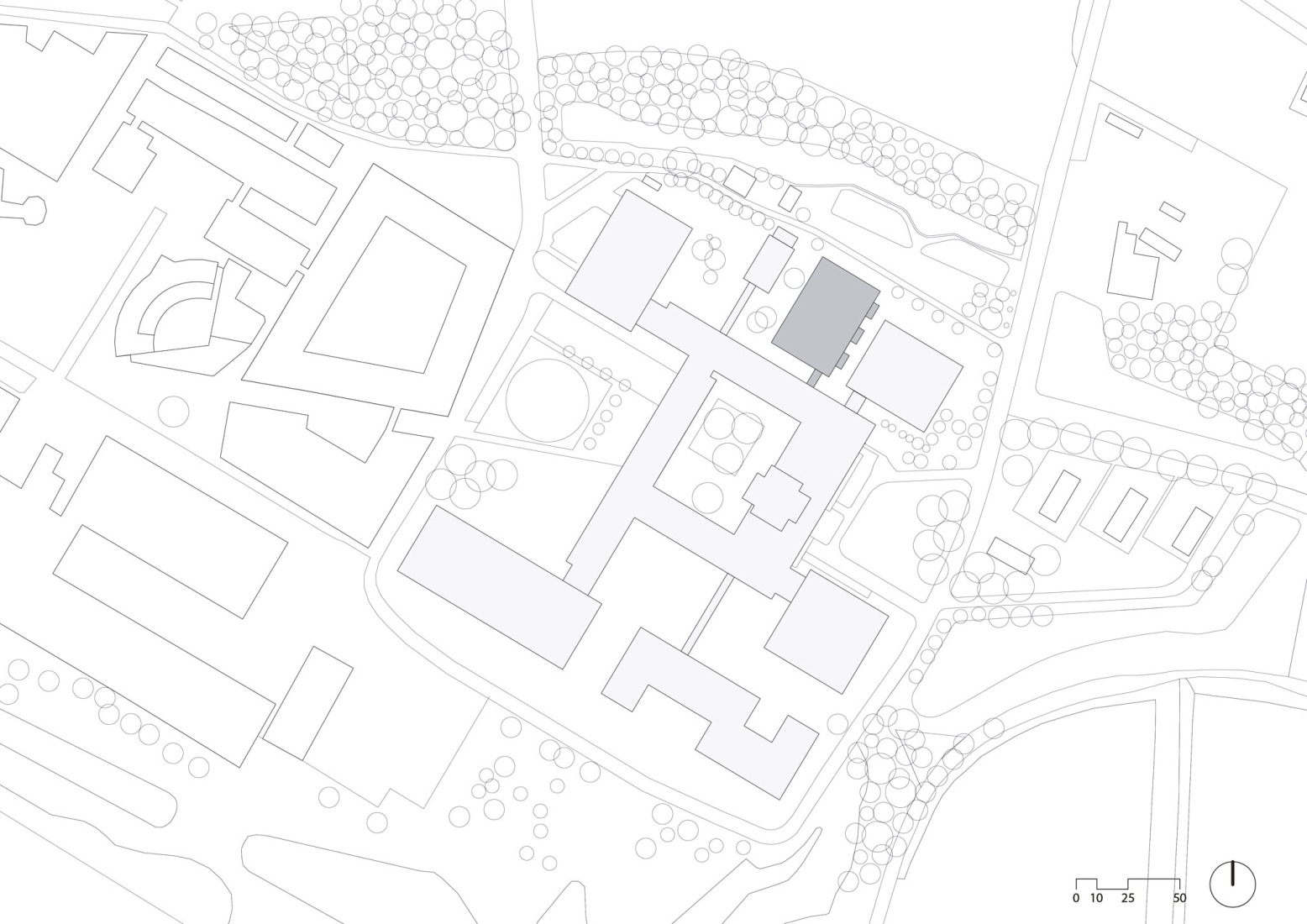

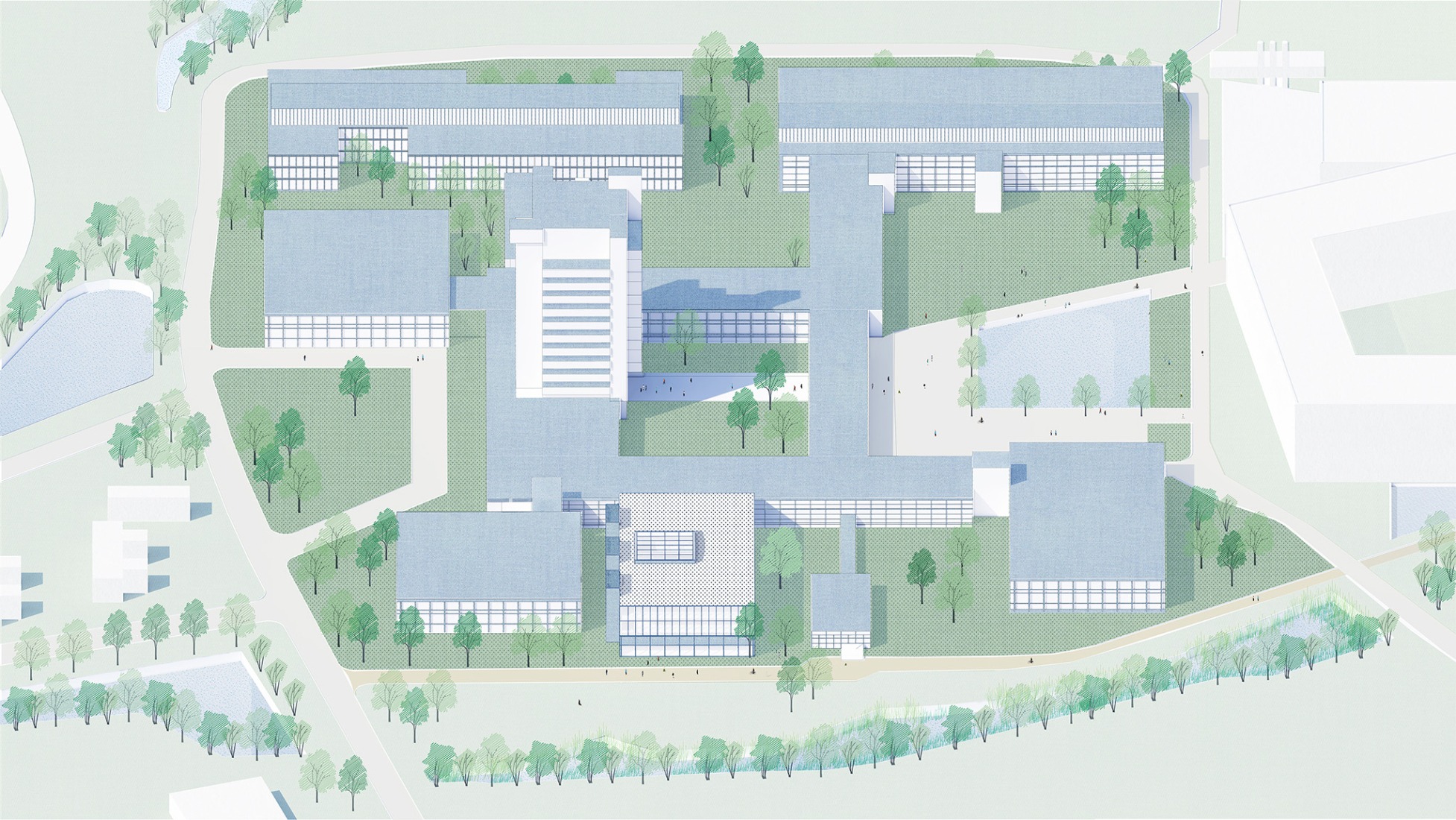

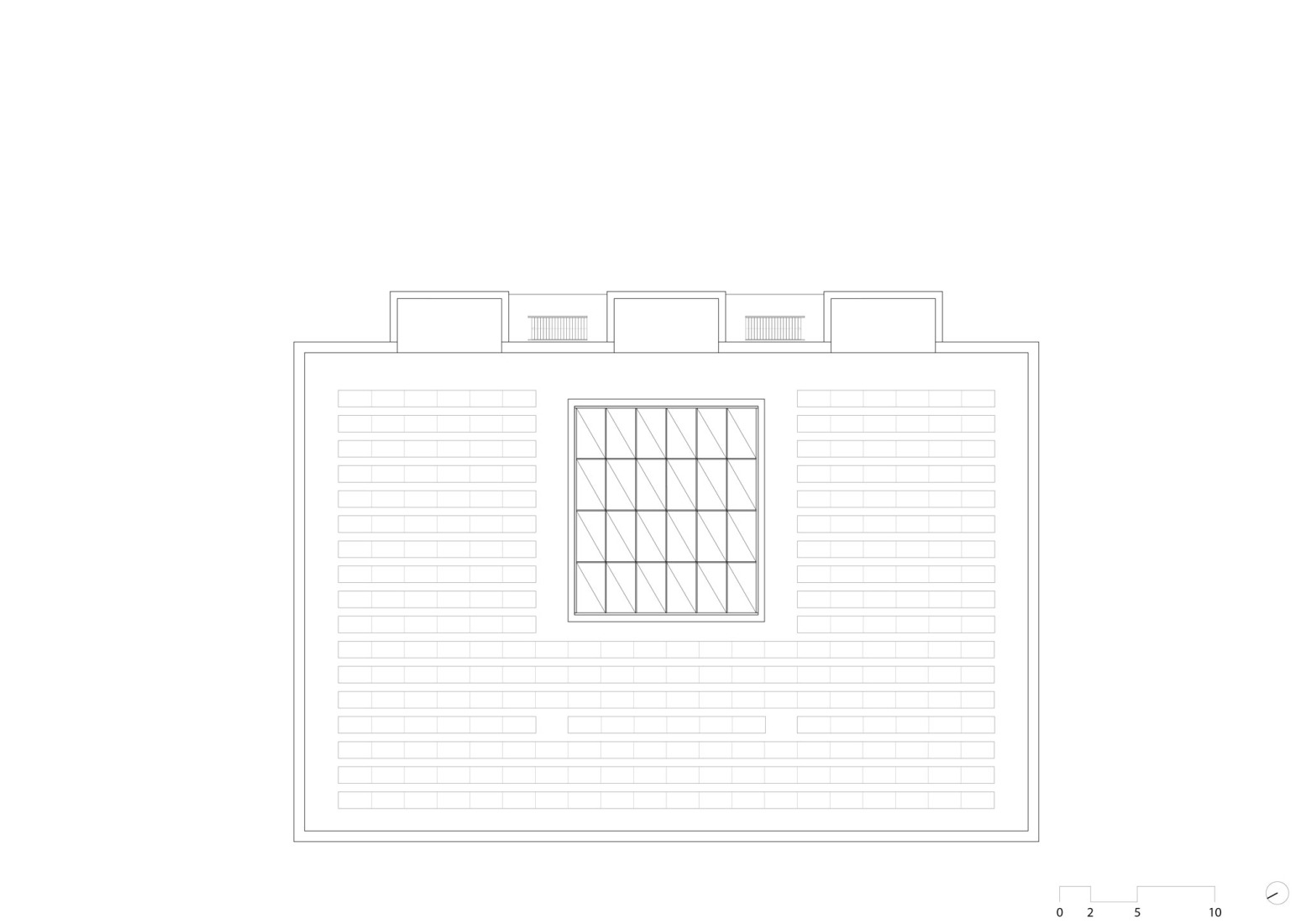

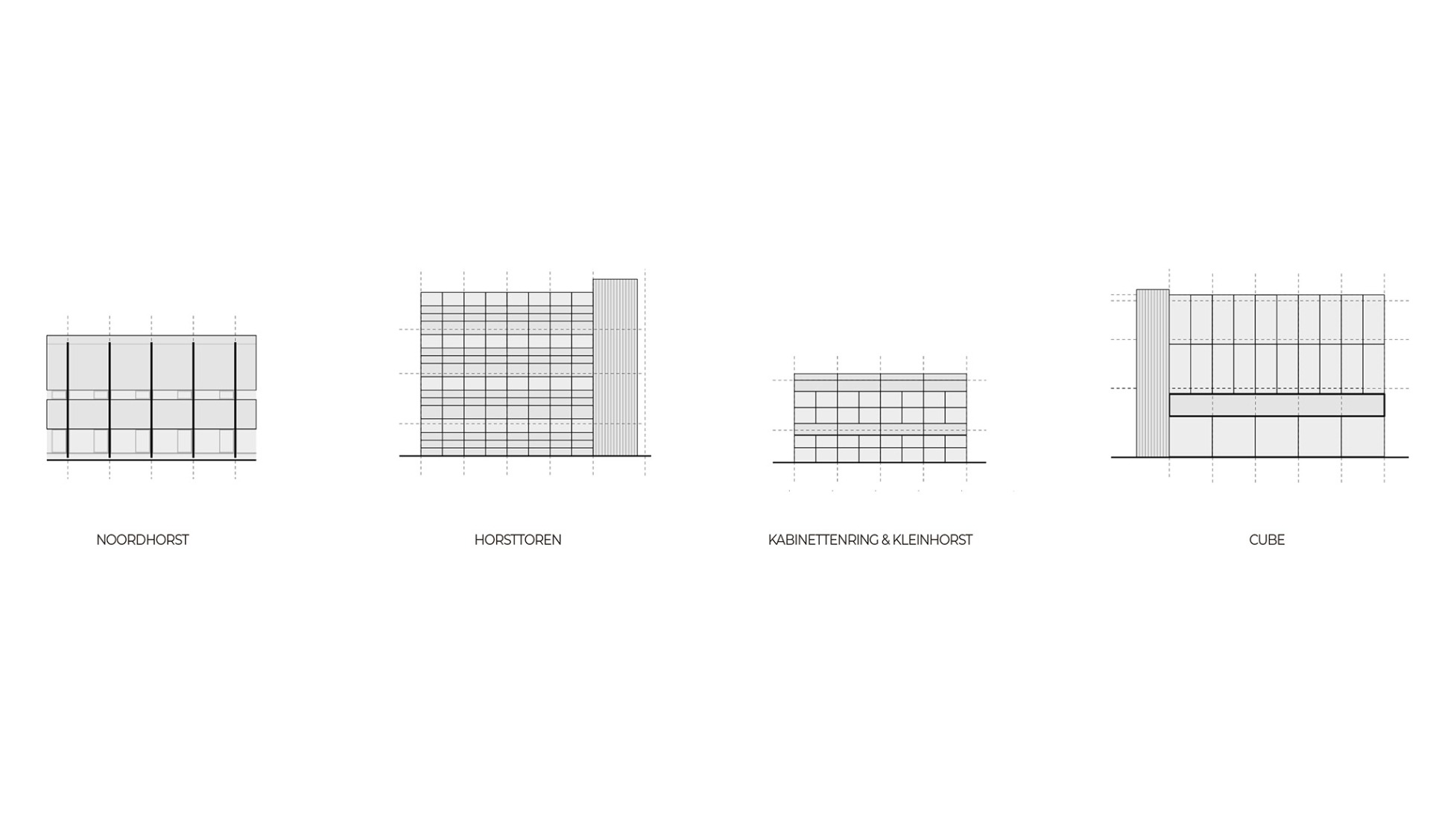

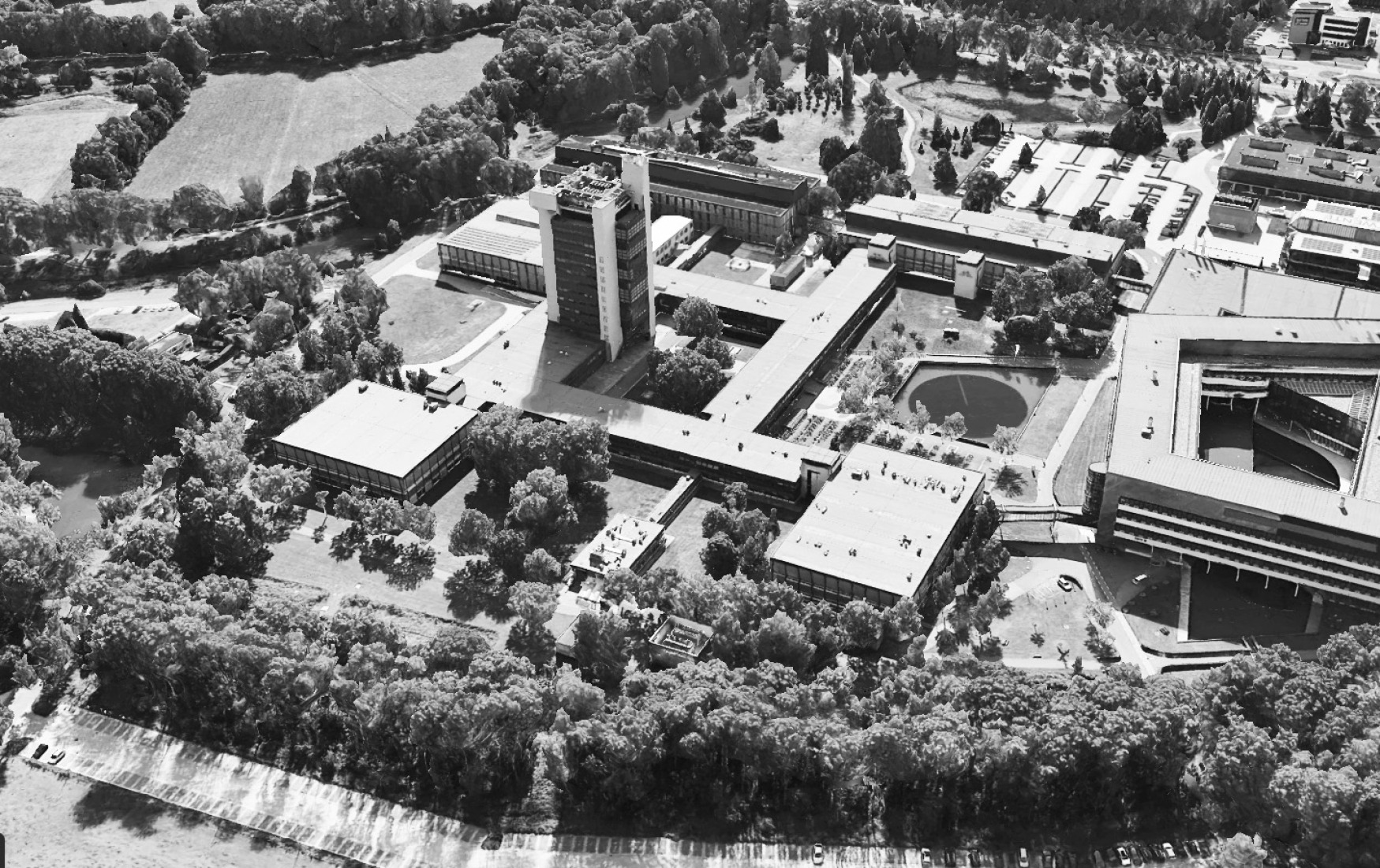

The Horst is one of the crown jewels of the UT campus. Designed in the 1960s by Dick van Mourik, the Horst is a modernist ensemble of low-rise carré, tower, and satellites. The new extension builds upon the original architecture with a contemporary interpretation. CUBE is conceived as a new satellite. The site was too small for the program. The solution: a smaller, linear volume with an extra floor. This keeps the Horst ensemble legible as a carré with satellites. The sunken ground floor limits the building’s height, while the three CLT cores echo the Horst complex’s characteristic service towers and visually slim the volume.

Modernism for a changing climate

The exterior relates to the Horst ensemble but is designed with greater climate awareness. Like the Horst, CUBE’s façade emphasizes the building’s organization. But unlike the rest of the complex, each façade is different. The building is oriented to open toward the northwest. Those façades are transparent, offering views of the landscape and diffuse daylight. The southeast and west façades are more closed, to prevent overheating.

The detailing is refined. The ground floor has wide windows with deep reveals overlooking the sunken workshop, like a showcase for Engineering Technology. Here, the façade is of wood, adding tactility and texture. Above it hangs a crisp glass curtain wall that aligns with the Horst complex. Behind it, the steel trusses are visible, giving the exterior dynamism through their geometric play with the orthogonal façade.

Sublime functionality

The architecture amplifies the building’s functionality. This principle guided every detail. Structural joints were endlessly refined, and fences, stairs, and façades were designed down to the smallest scale. The material palette is simple and clear, fitting the functions. Steel trusses provide the large spans, coated fire-resistant blue to emphasize spatial structure; light gray floors and recycled PET ceilings add calm and light reflection; glass partitions maximize visual connection. This robust base is supplemented with larch frames inside and out, adding warmth. The CLT cores reinforce this. Exposed installations are precisely designed and contribute to the building’s technical character. The whole building breathes “Engineering Technology.”