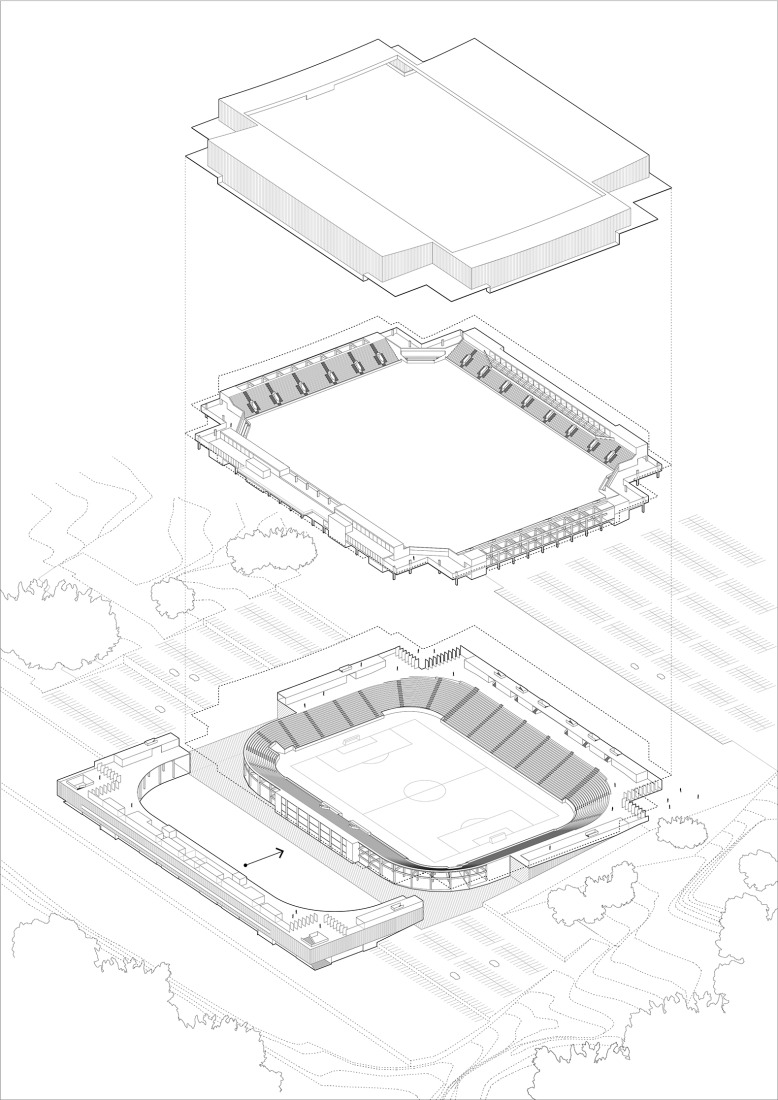

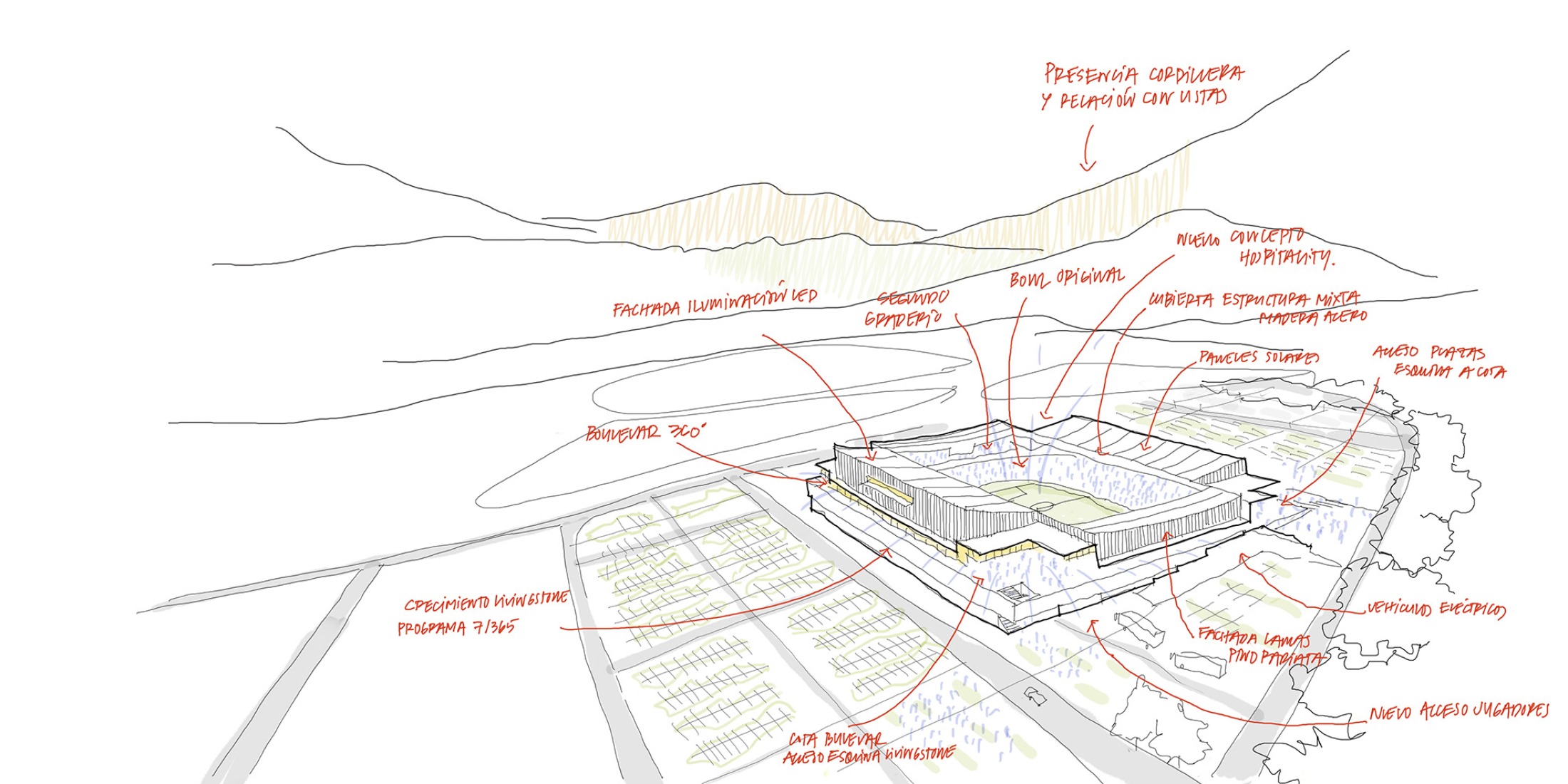

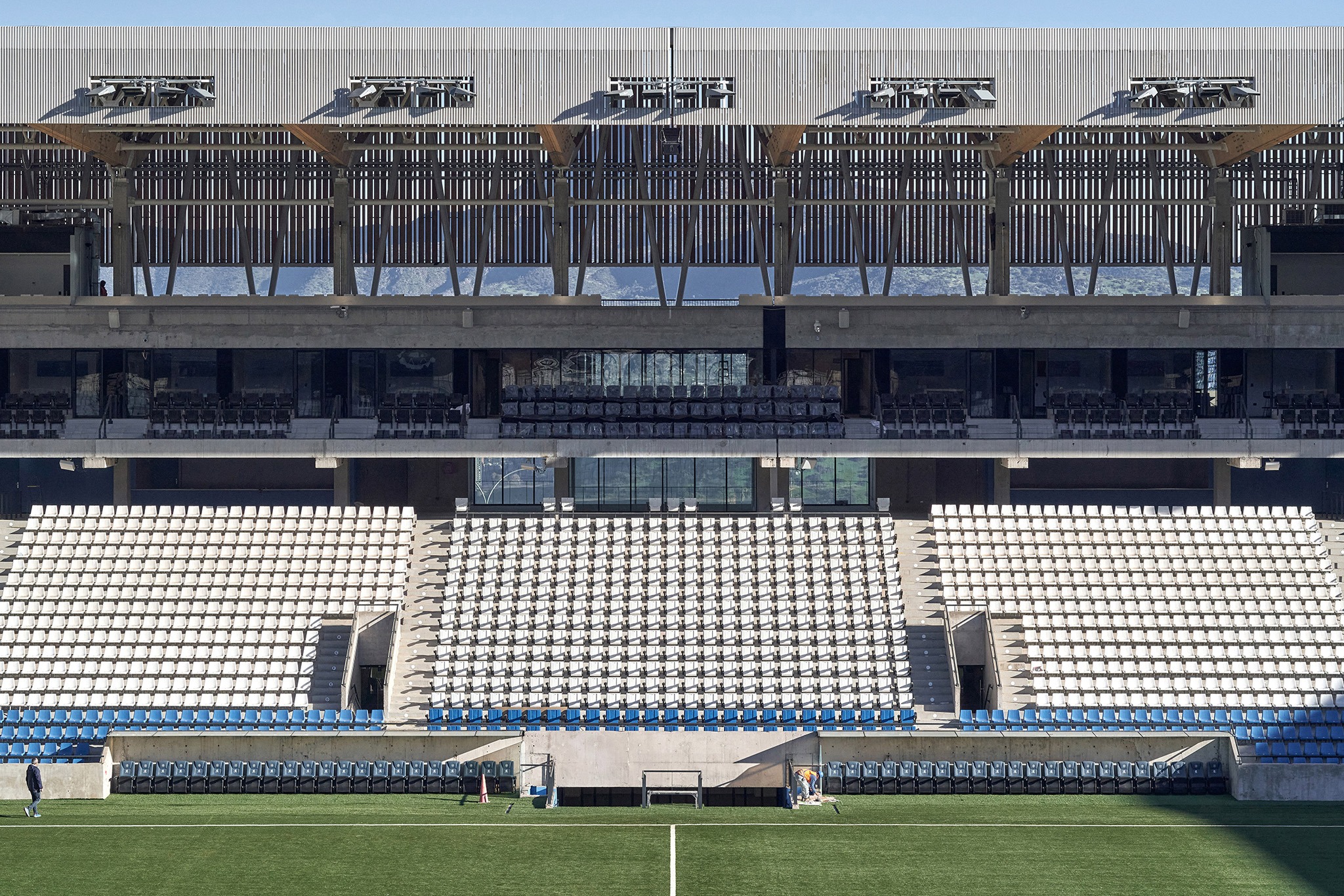

Preserving the original stands virtually intact, IDOM's intervention consists of the addition of a continuous horizontal plane that links the different areas around the perimeter. Above this connecting boulevard, a light and permeable structure houses the required expansion program.

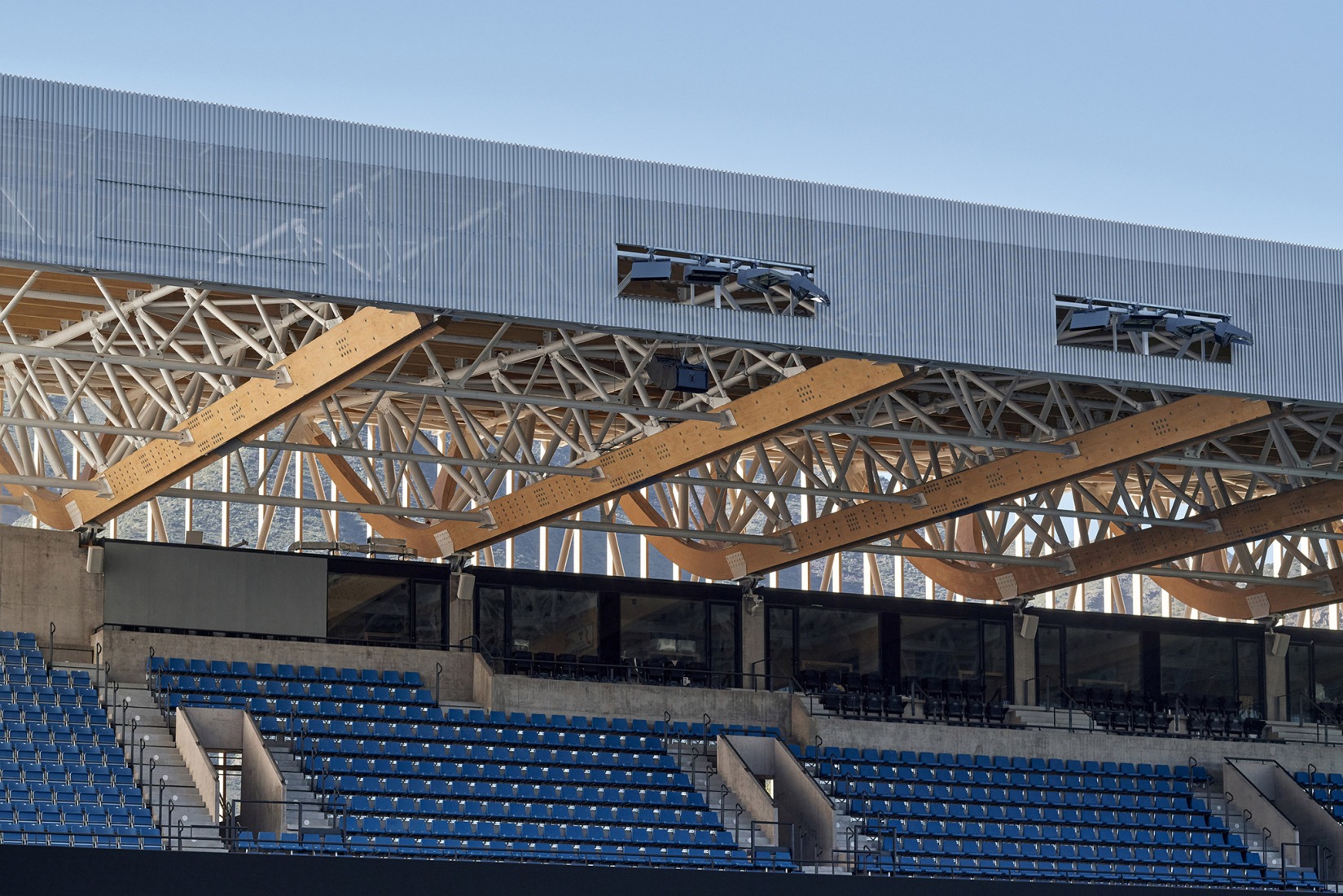

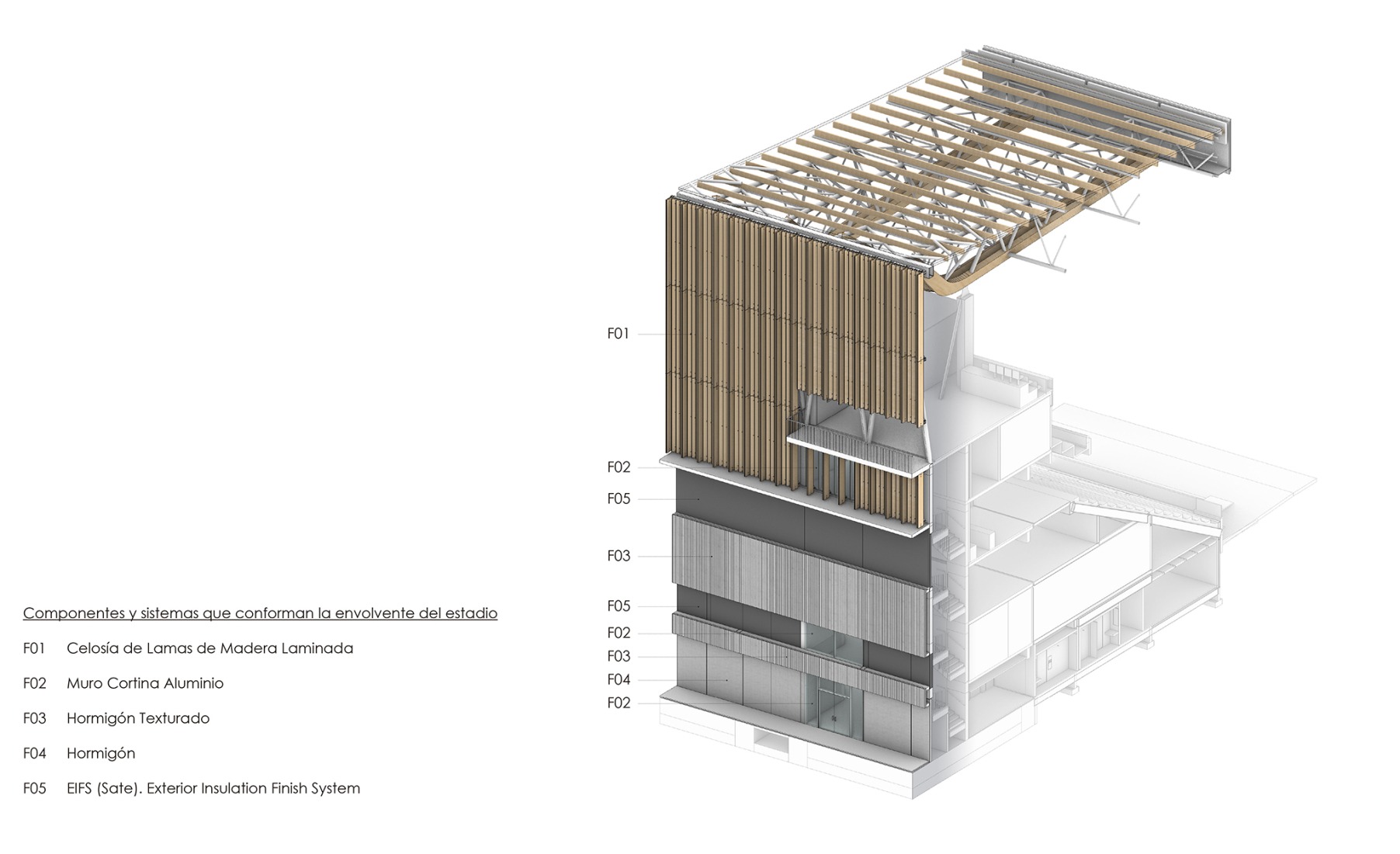

For its construction, the proposal retains the original stadium's concrete structure, adding a second tier of reinforced concrete and a roof with a mixed steel and wood structure. In line with sustainability criteria, the proposal applies the principles of reduction, reuse, and recycling, circularity, and the active participation of industry in the project.

Modernization Project of Universidad Católica Stadium by IDOM. Photograph by Cristóbal Palma.

Project description by Borja Gómez and César Azcárate

Location and Concept

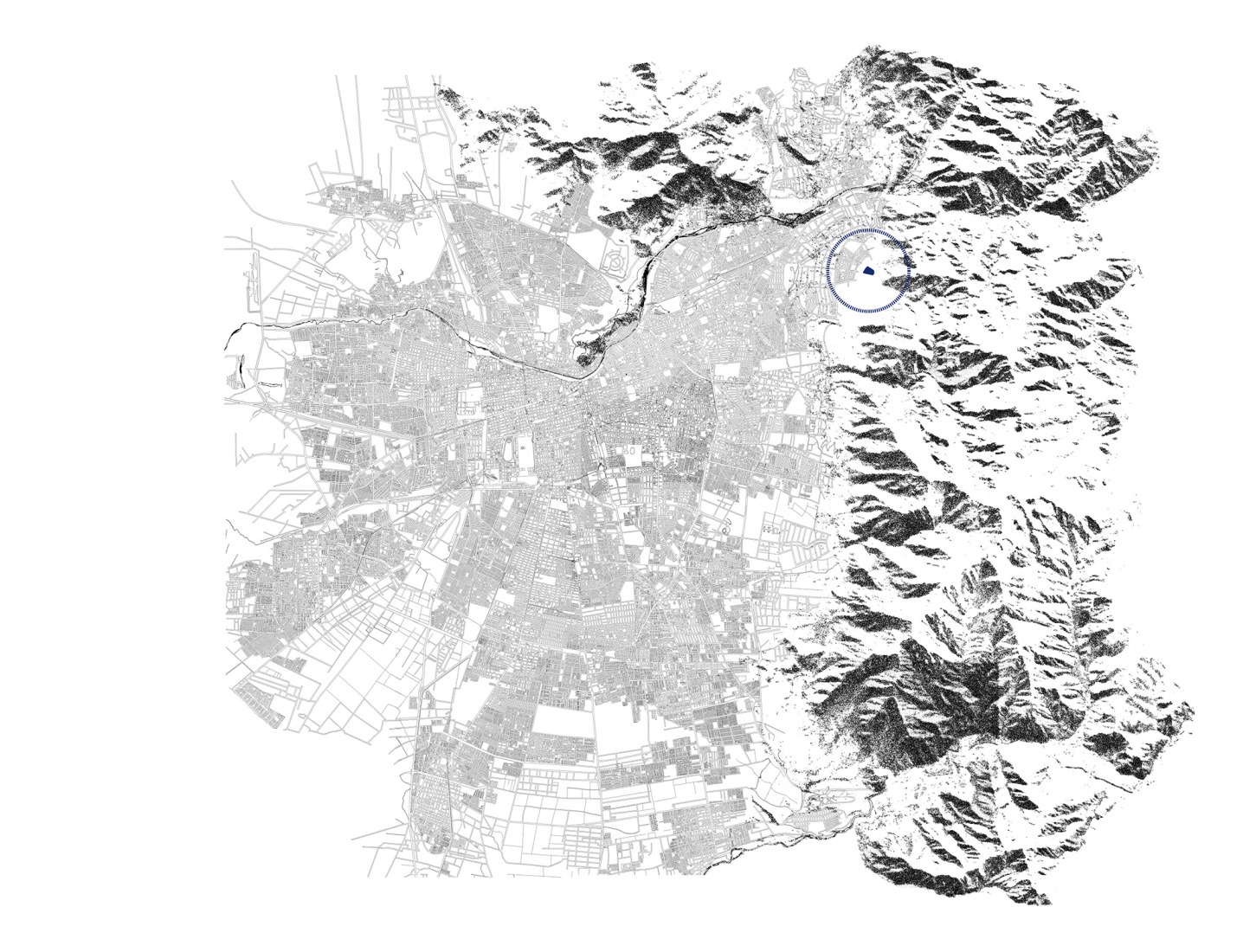

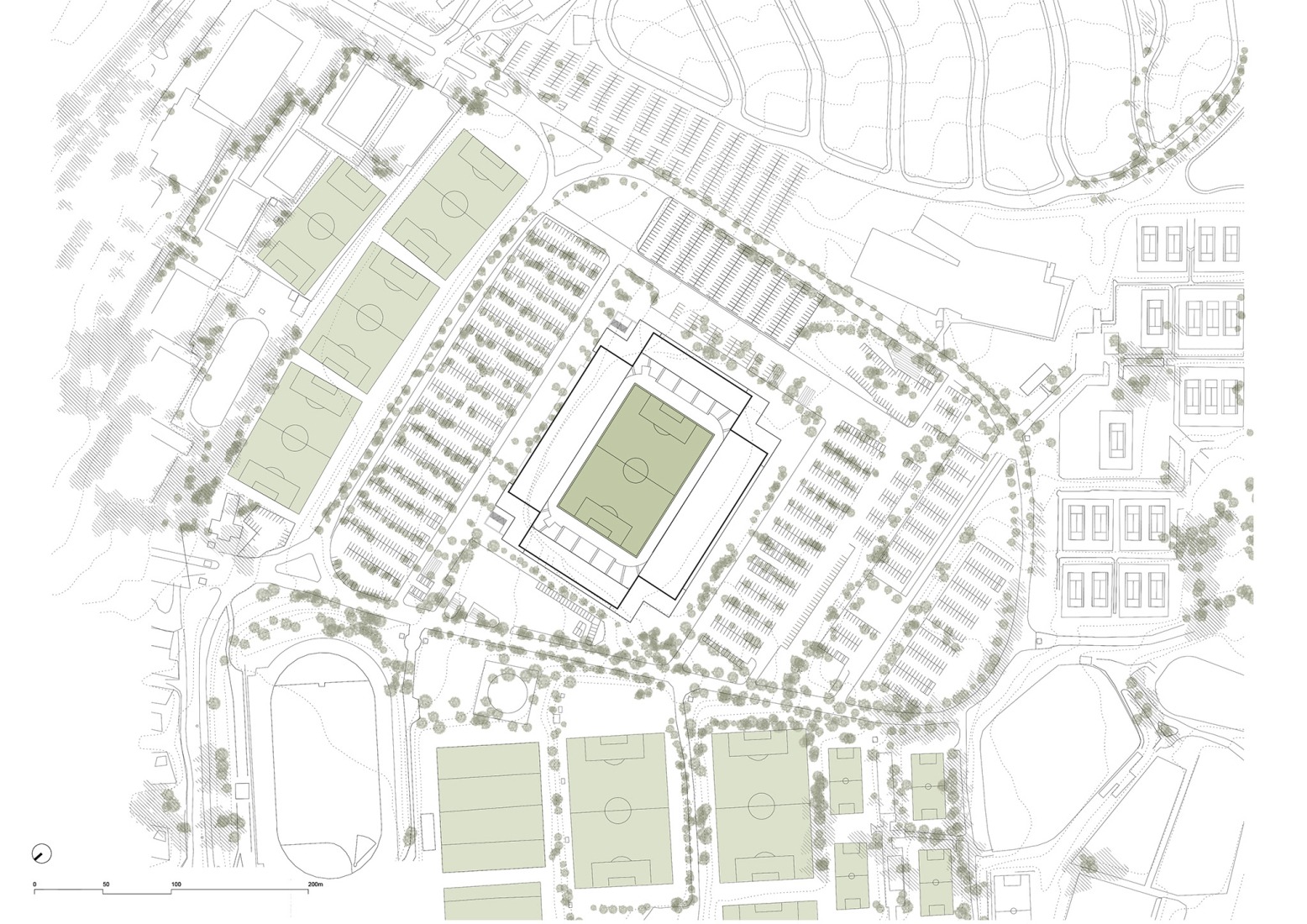

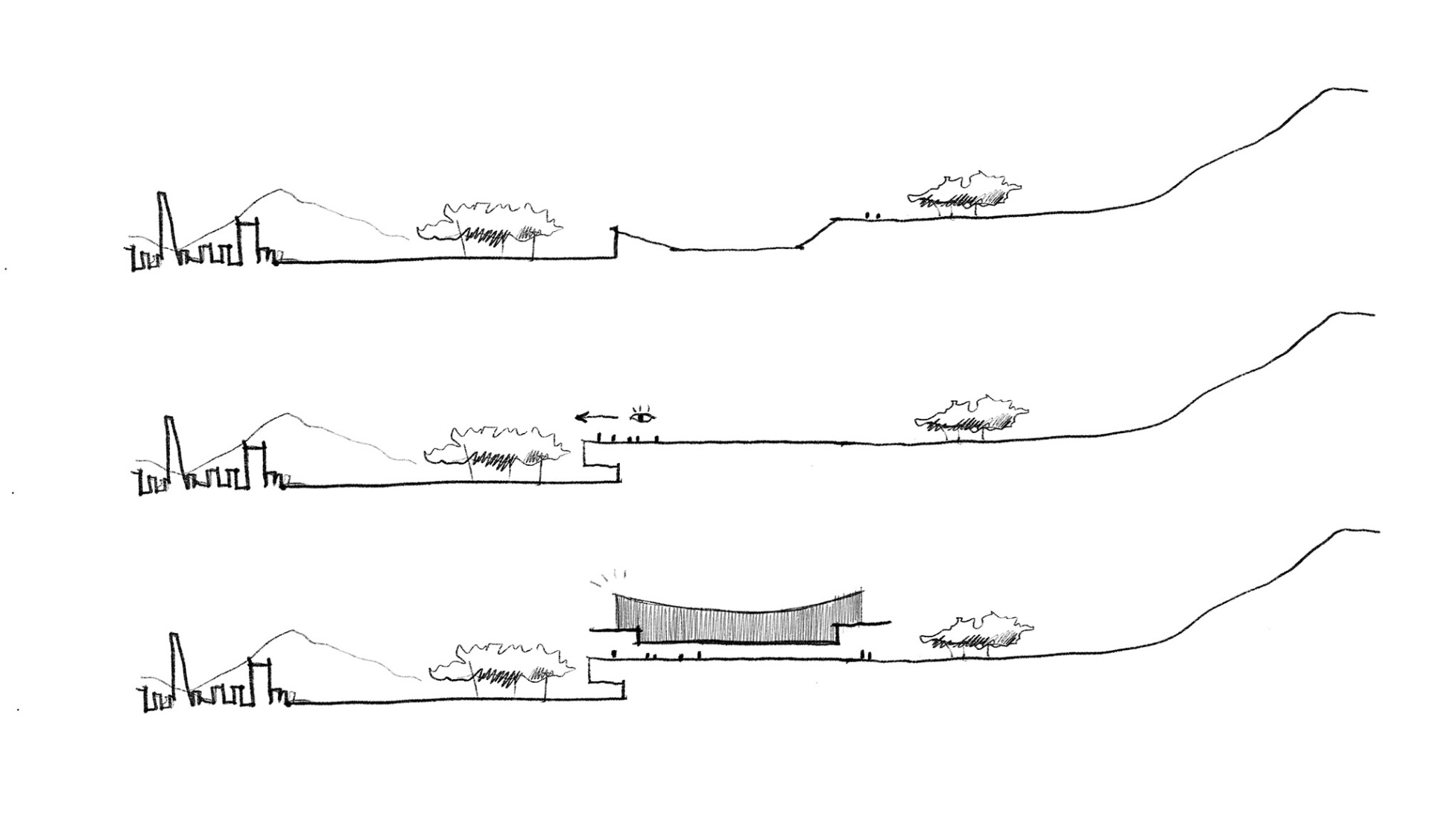

The San Carlos de Apoquindo Stadium, currently known as the Claro Arena, was officially inaugurated on September 4, 1988. Located in the Las Condes district of Santiago, Chile, the stadium sits in the foothills on a gently sloping site facing the city.

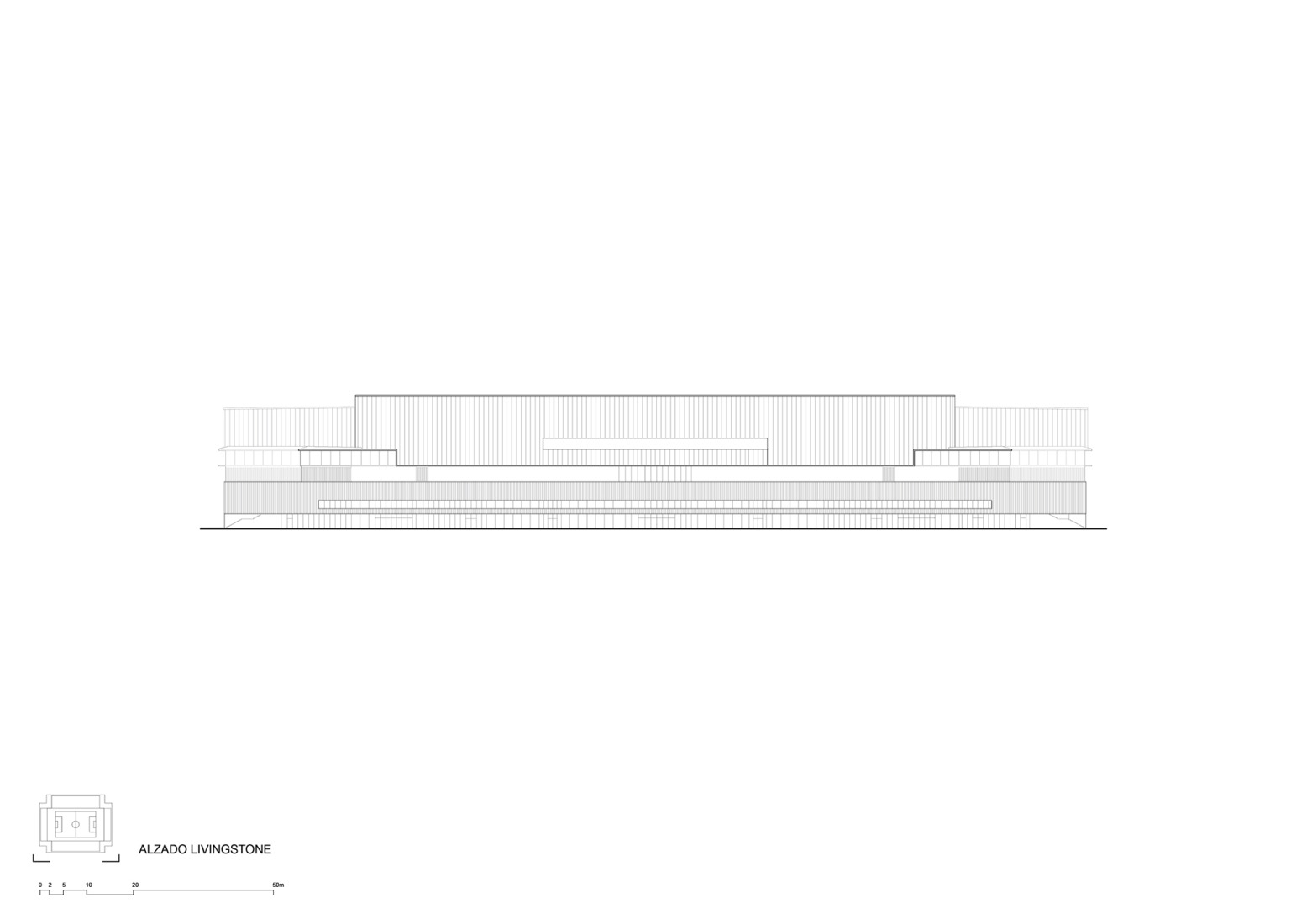

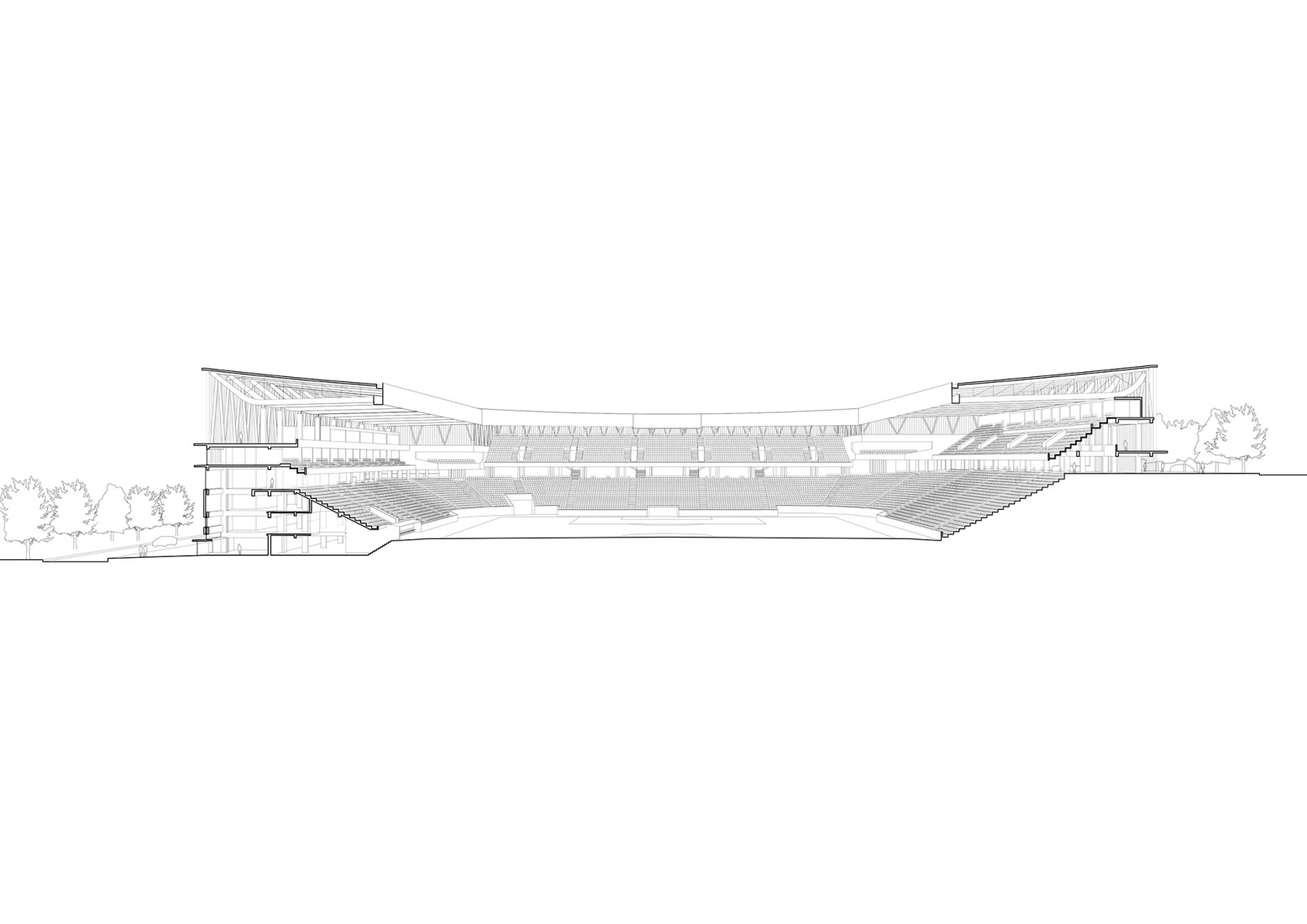

The stadium was partially buried, with access at ground level on the east side, facing the foothills (called Fouilloux), and on the west side, facing the city of Santiago (called Livingstone). The mountain range is on one side, with Cerro Provincia dominating the view. Manquehue and the city of Santiago are on the opposite side.

Given the evolution of world football since its inauguration and the need to increase capacity from 12,000 to 20,000 players, the club launched a competition to address the modernization needed to meet the infrastructure's present and future challenges.

The new stadium must address issues related to television broadcasts, as well as technological, sustainability, comfort, and hospitality issues specific to modern soccer. The competition's focus also anticipated the aspiration to design a multipurpose building for ongoing activity, rather than limiting its use to two sporting events per month.

At IDOM, we designed a modern soccer stadium in accordance with the highest standards. We conceived it as a rational building with a rigorous approach to the program, structure, and sustainability. The project considers the sun, wind, energy consumption, and interior and exterior comfort. The stadium has spaces to host activities 365 days a year and expands the hospitality offerings. Tailored to the club, the building is rooted in its tradition and history. Built from local materials, it offers an authentic soccer atmosphere outside while being visible from and respectful of the surrounding area.

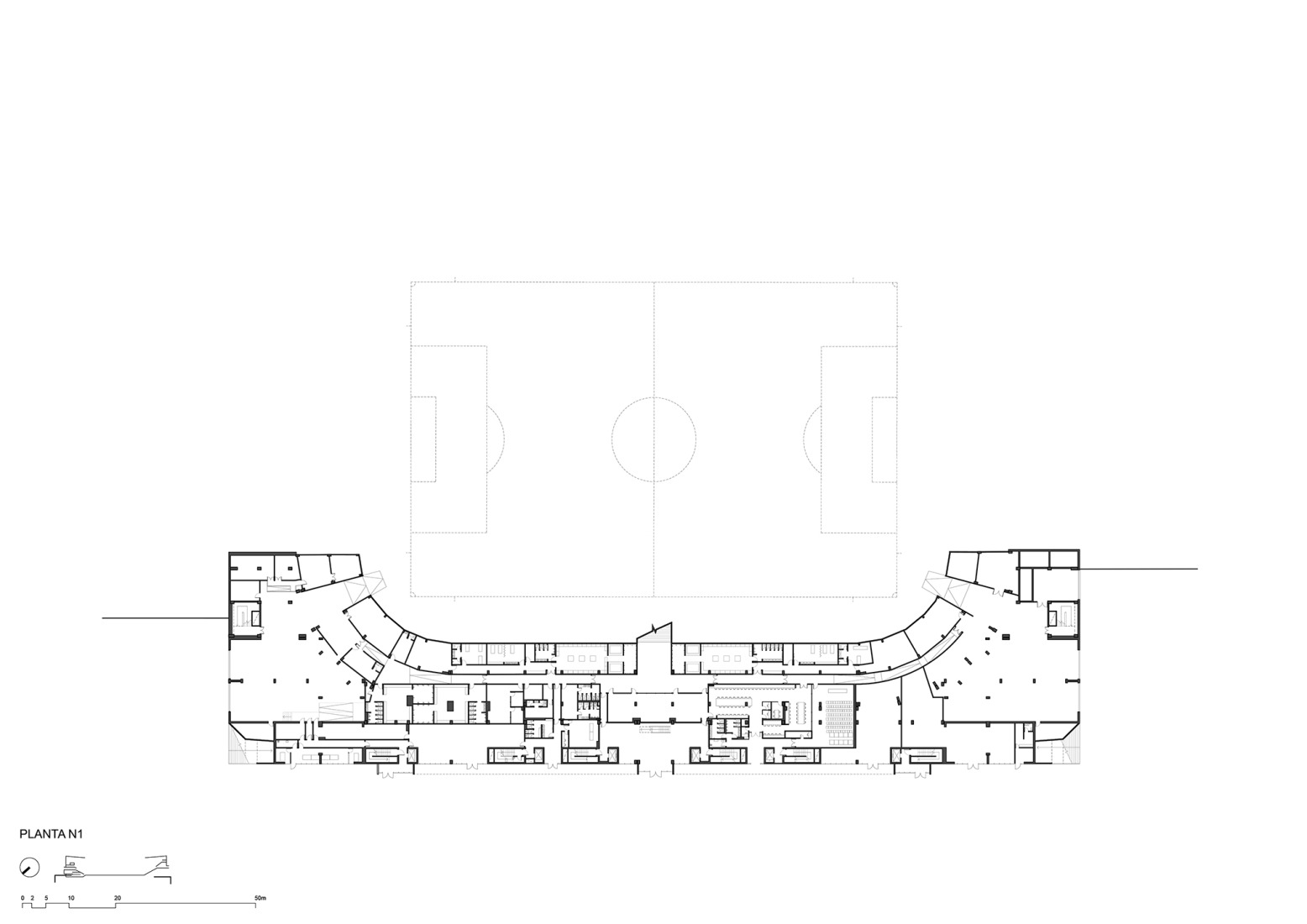

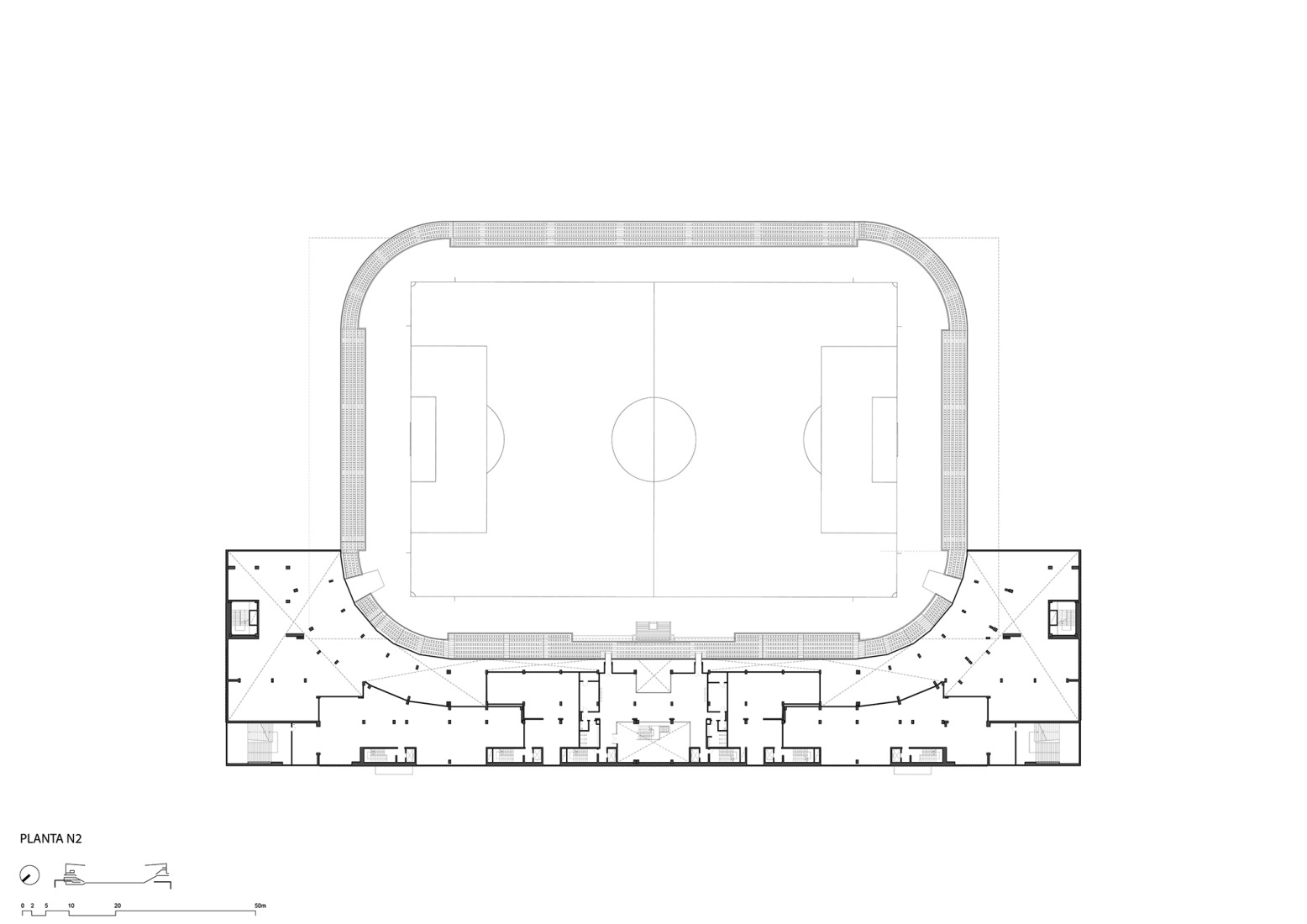

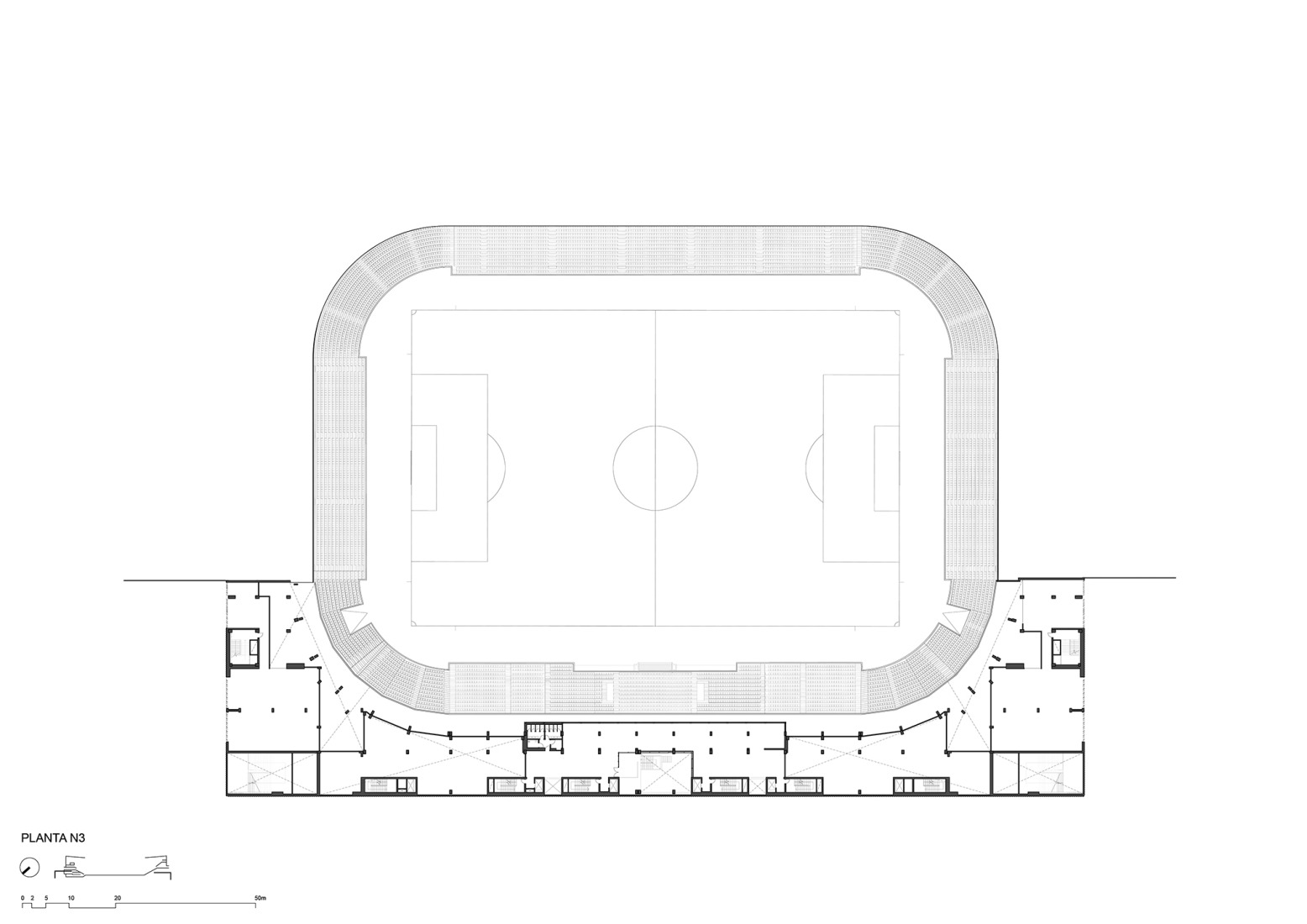

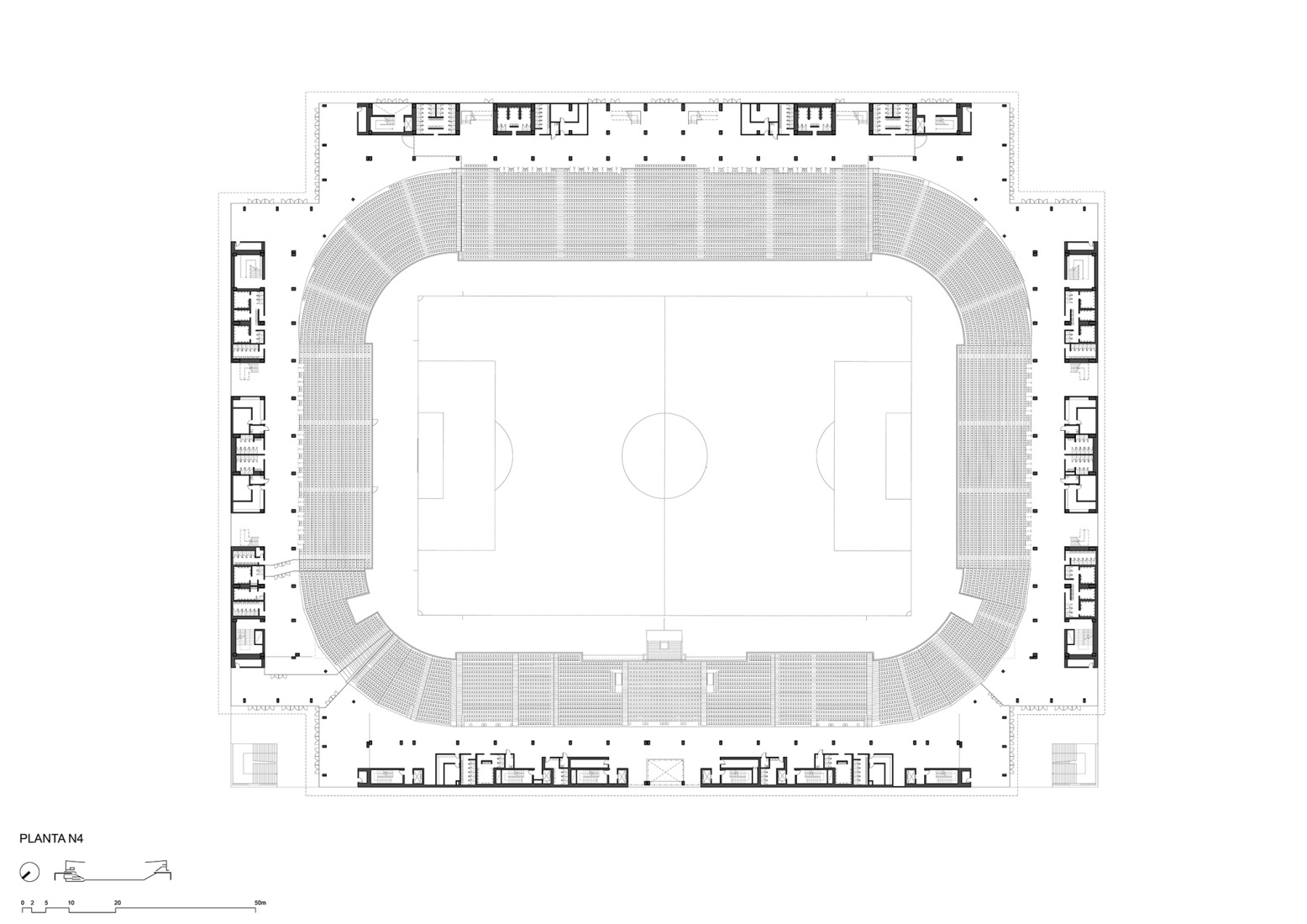

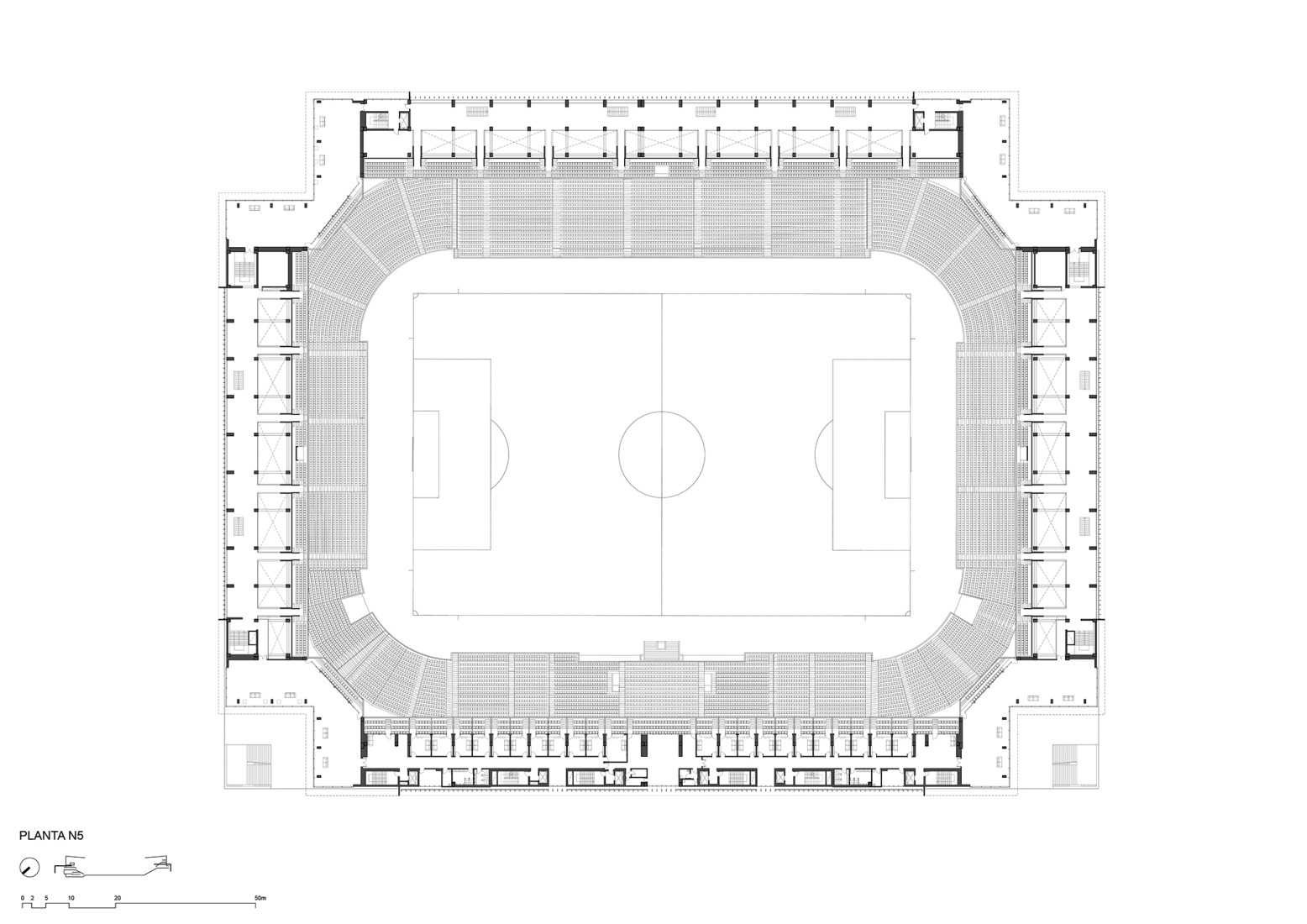

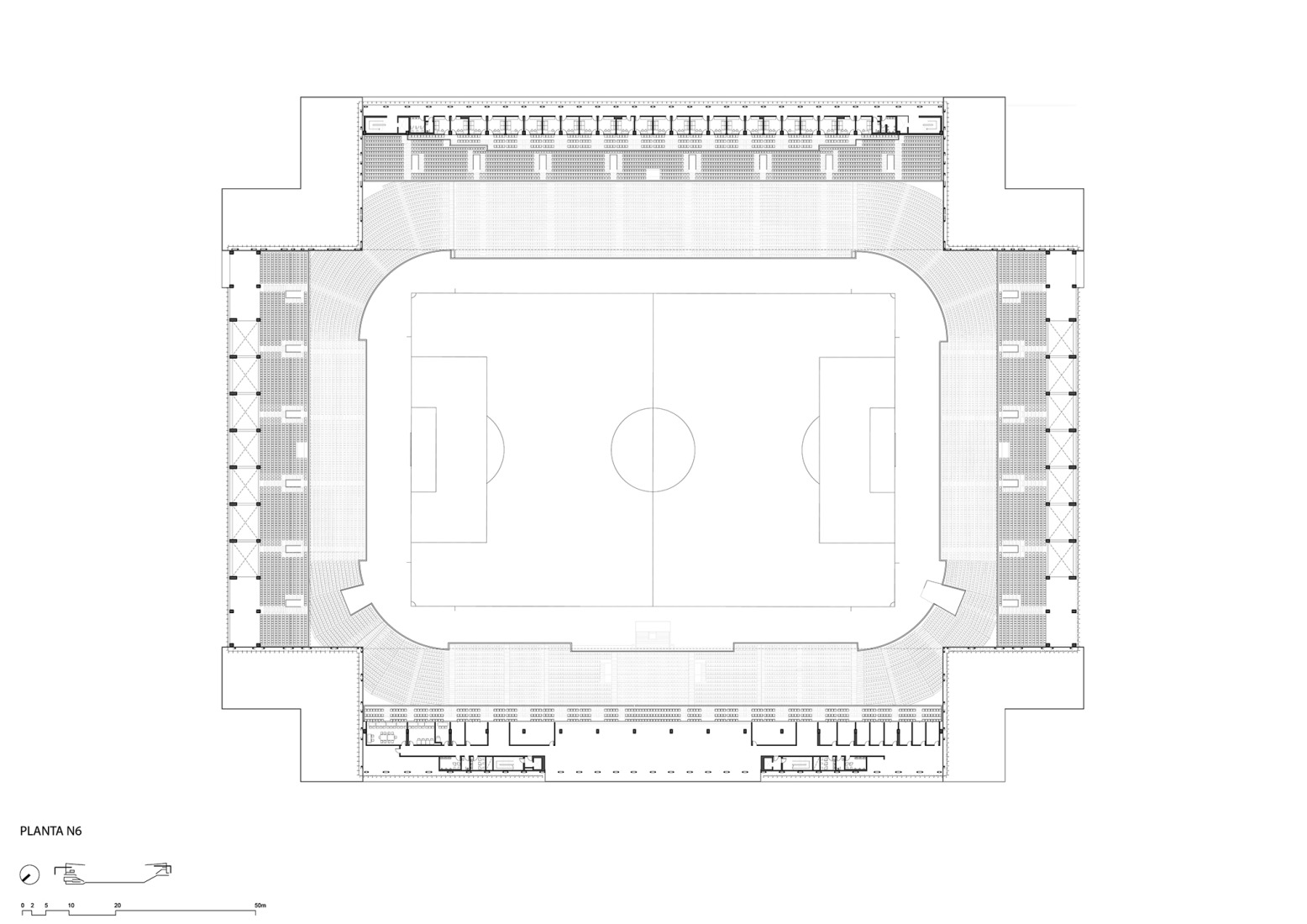

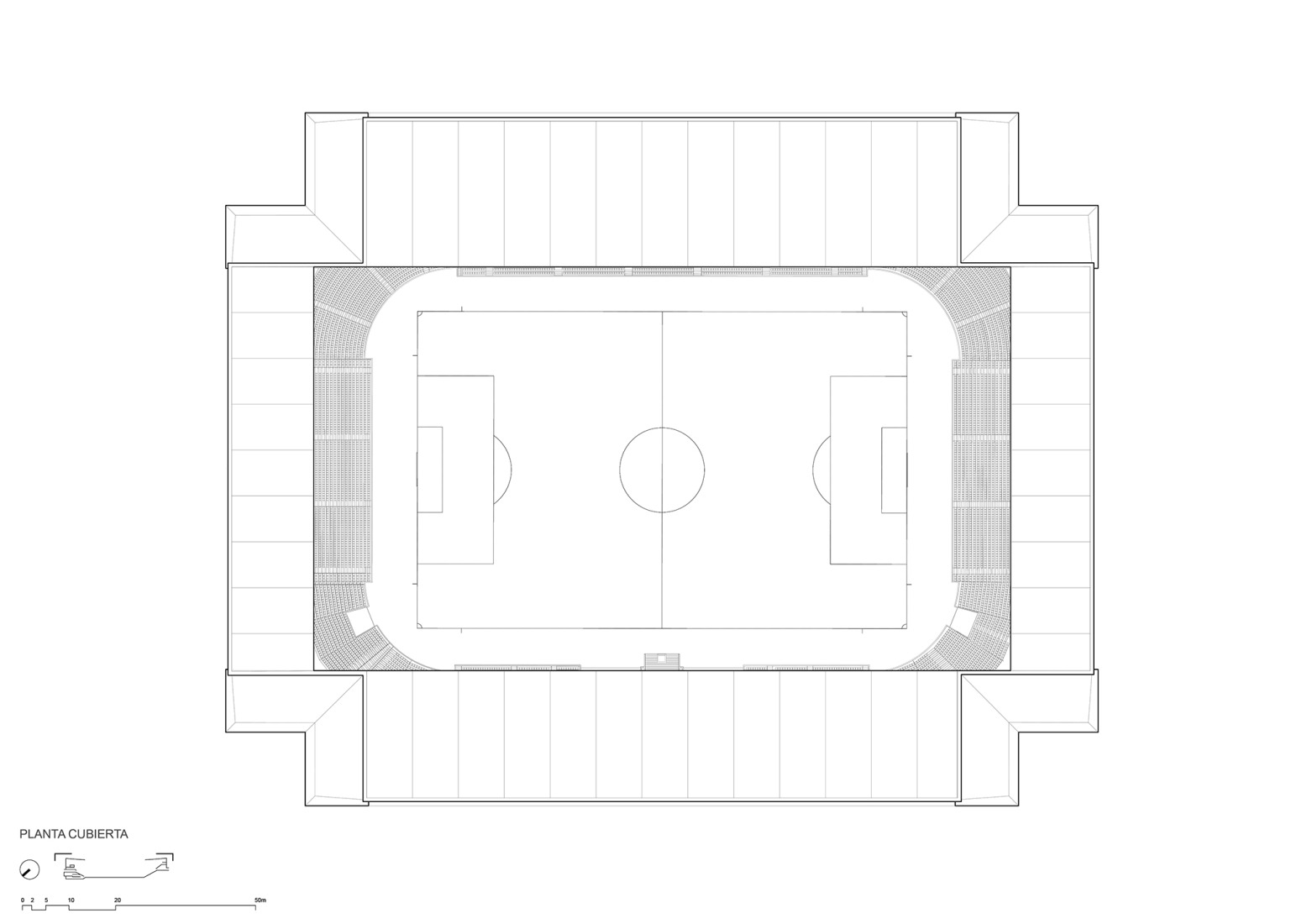

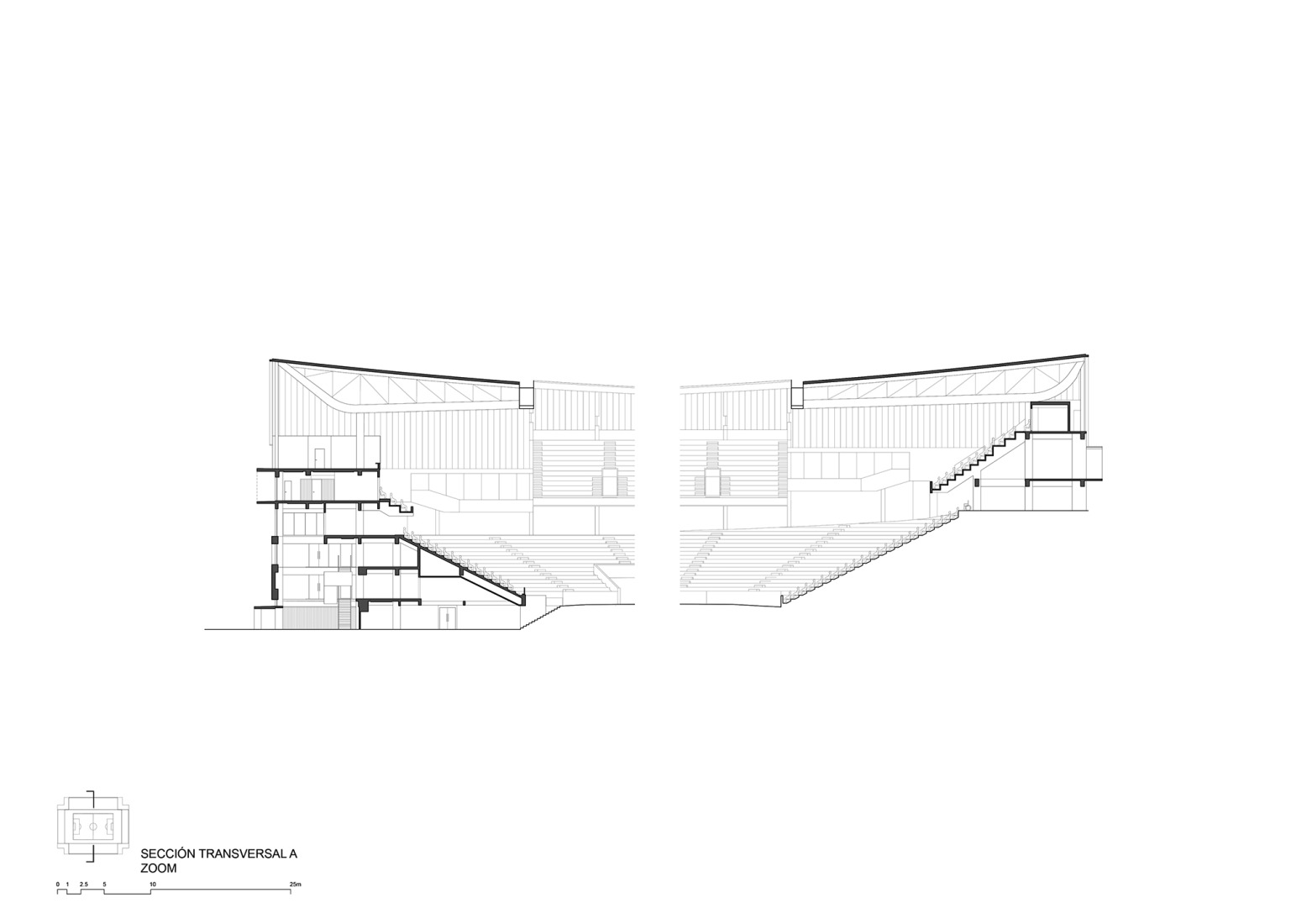

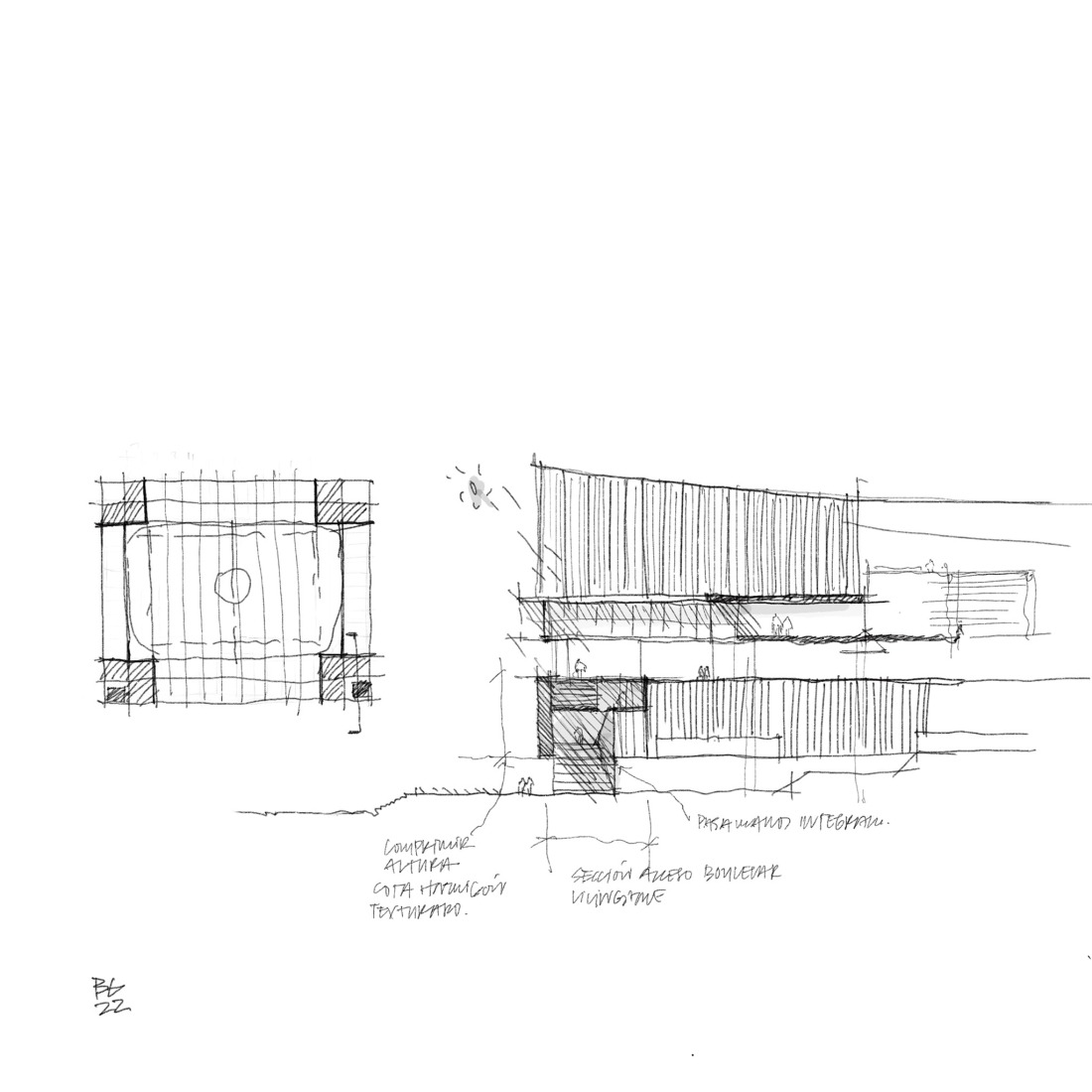

This section illustrates the process. While keeping the current stands practically intact, a continuous horizontal plane connects the bands and backgrounds to the Fouilloux access level, a 360-degree boulevard. The old stadium is anchored to the ground under this boulevard, and the extension with a lighter and more permeable structure rises above it. In terms of layout, we opted for the most efficient geometry: a rectangle. Rather than curving and obstructing visibility, the corners were transformed into distinctive features that mark the building's entrances and provide spectators with unique spaces.

Program (function)

The lower stands of the original stadium offered excellent views that could be preserved with very few modifications, maintaining almost 95% of the original views. The 360-degree boulevard is located on the upper level. New galleries are being built above the boulevard to house the general public in the back and the general public and boxes in the Fouilloux area.

In Livingstone, the expansion is taking place below and above the boulevard. Towards Santiago, below the boulevard, the new building will house new sports facilities, including dressing rooms, press rooms, and press work areas, as well as hospitality spaces, such as third-tier and premium areas, including VIP and presidential boxes. It will also house television, radio, and technical areas.

Additionally, four rooms in the corners will offer views of both the landscape and the sporting event. These multipurpose rooms can be used during games and events and are connected by the slabs behind the stands, which opens up the possibility of using the infrastructure in new ways for non-game events.

The playing field's surface has been modified to be at the optimal height for maximizing visibility.

Structure and roof

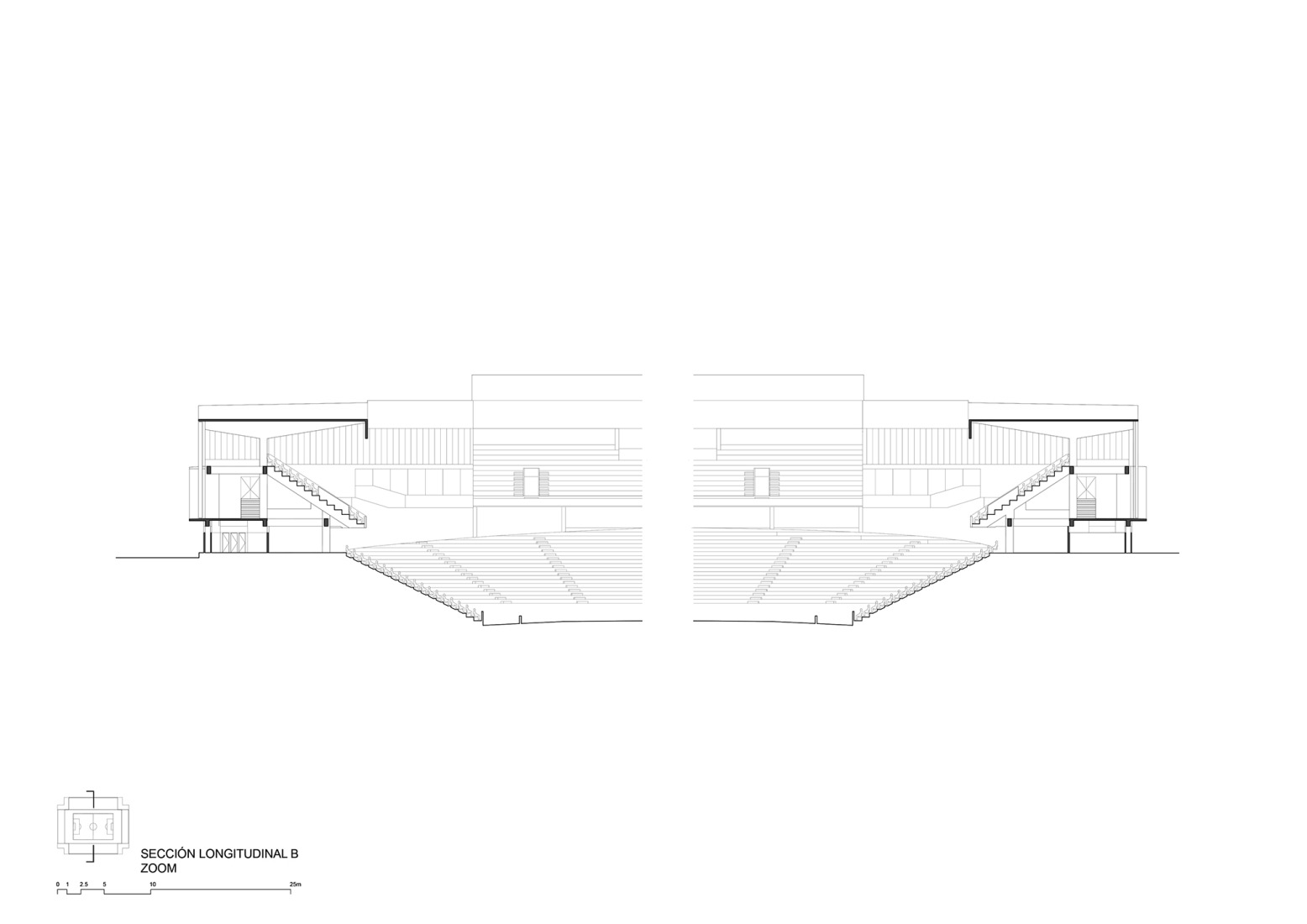

The original building's entire concrete structure remains intact and in good condition. Therefore, the decision has been made to intervene as little as possible.

This meant that the stadium extension had to be built around the existing bowl.

A concrete beam and pillar skeleton with reinforced slabs around 18 centimeters thick completes the building's geometry at the ends and sides, along with their corresponding expansion joints. The expanded corners of the building are covered with an inverted mixed concrete-steel structure that optimizes the use of steel in tension areas while leaving concrete exposed inside rooms. Building height is regulated by law, and floor heights are limited by those of the original Livingstone building, which are very restrictive in some areas. These are the necessary boundary conditions to which the building must adhere.

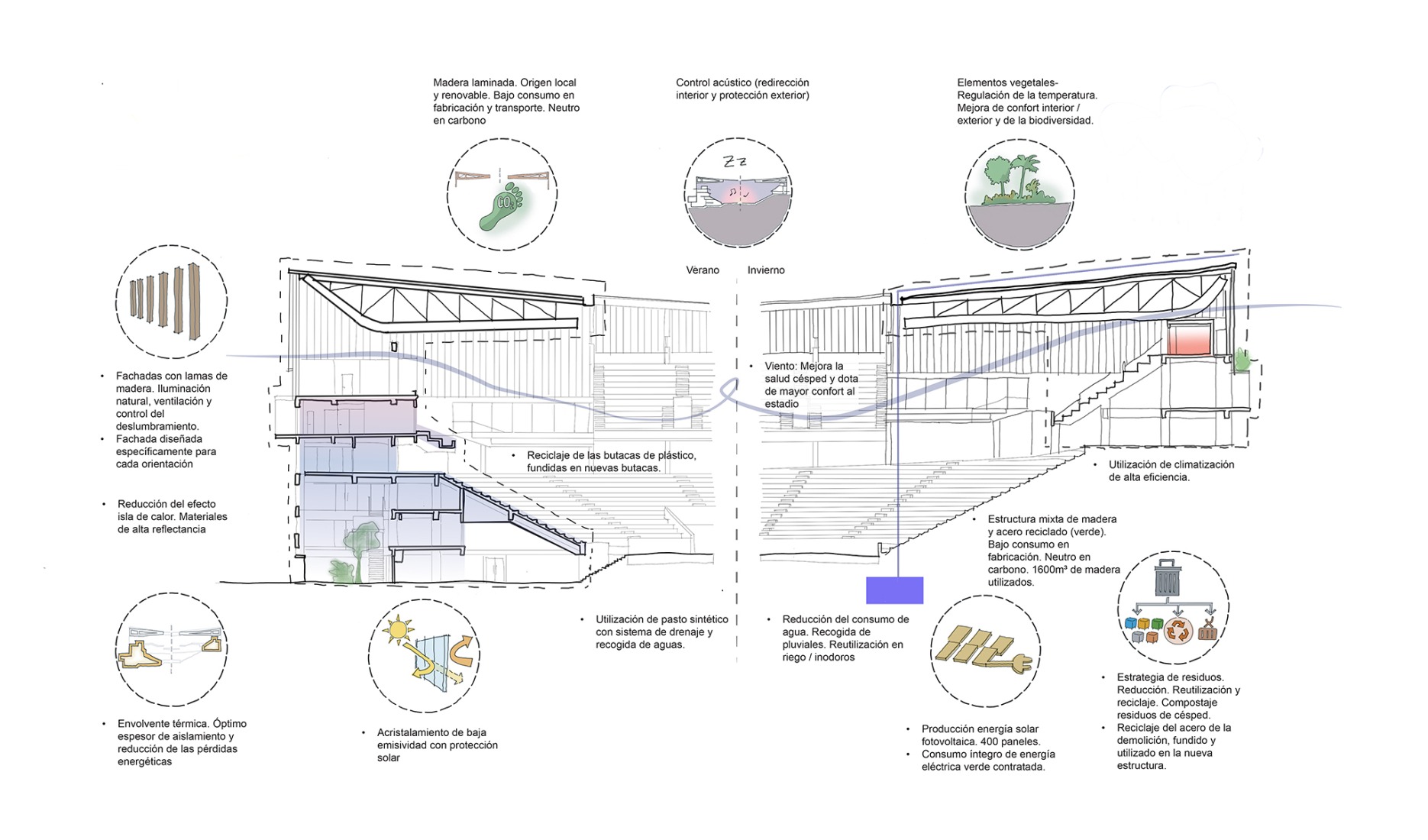

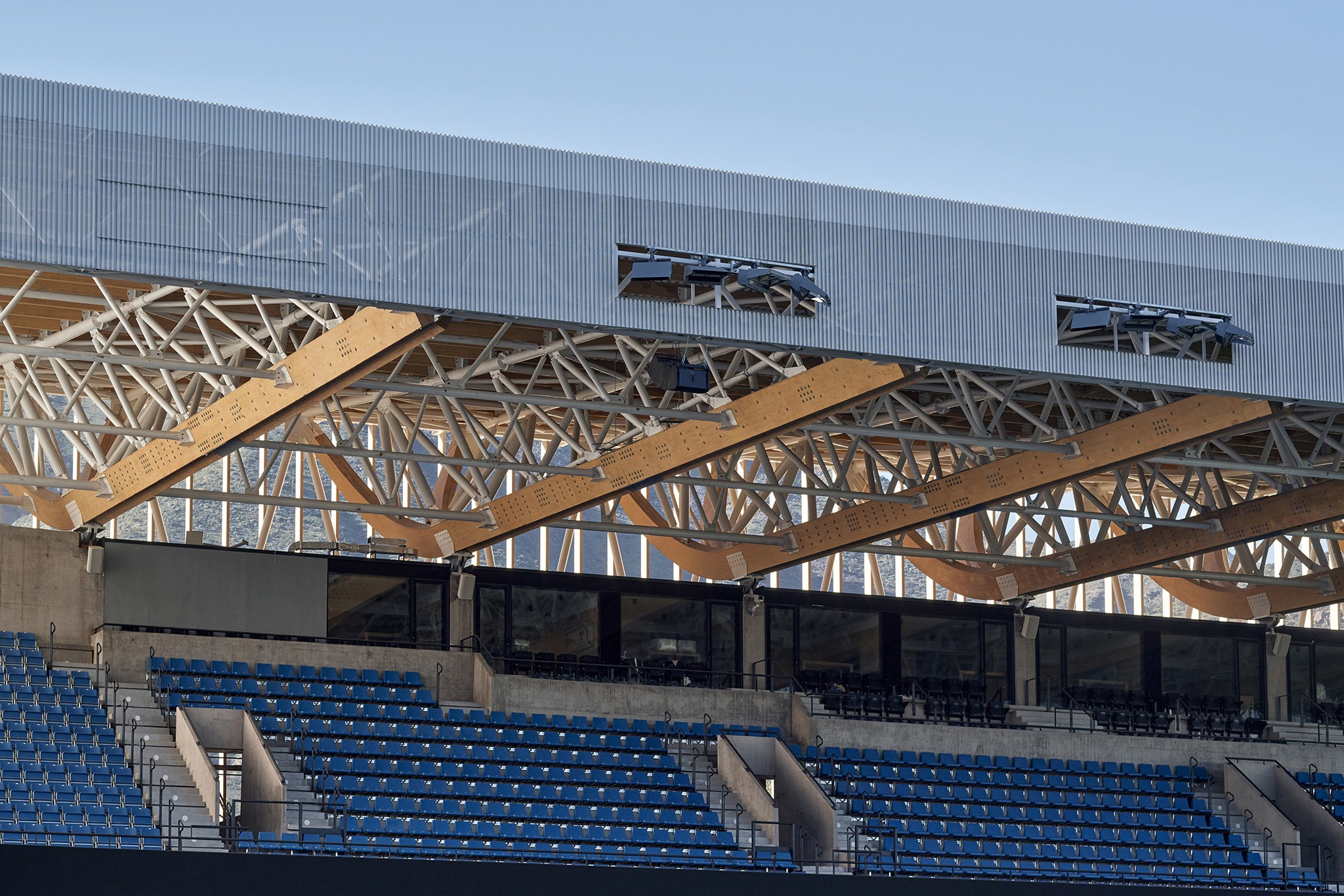

Due to Chile's seismic conditions, we proposed a lightweight roof to limit the load at such a height above the ground. Chile is a country rich in wood. Thanks to the development of local technology and a strategic alliance between the club and the timber company CMPC, we were able to design a mixed wood and steel structure.

The roof structure is designed through multiple stages and iterations to conclude with the most efficient solution. The appropriate structural type is used for each span. At the ends, solid laminated wood beams span 17 m every 8 m. At the sides, a three-dimensional mixed wood-steel structure is designed with supports every 8 m. This structure spans 27 m in Livingstone and 31 m in Fouilloux.

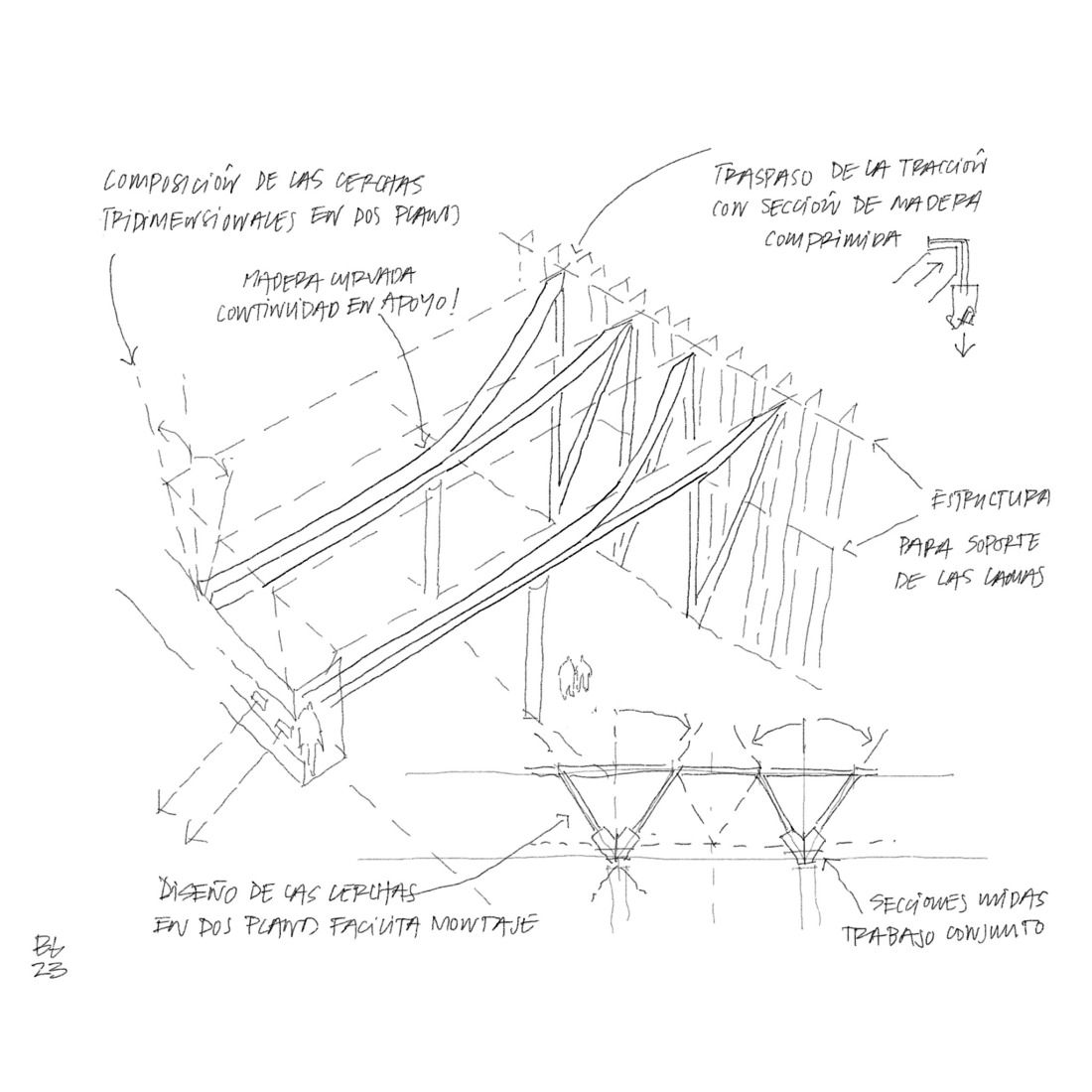

Chilean engineer Mario Wagner proposed this structure, which can be understood as the deployment of two flat trusses that rotate to open up into the upper chord, taking the compressed lower chord as their axis. This reduces the span of the wooden purlins (rafters) of the roof. The lower wooden chords are made of curved laminated wood profiles so that forces are transferred to the pillar by compression. This minimizes the need for steel in the anchor plates. However, the pieces must be stabilized in their position. A light sheet metal and TPO waterproofing complete the roof package on top of this.

Enveloping, sport confort

The competition had already proposed a solution for the façade that would improve the interior and exterior environmental conditions of the bowl. Since it is an open, un-air-conditioned space, the façade is designed to reduce afternoon glare, control noise emissions, and facilitate ventilation.

From the boulevard level to the roof, the building envelope is made of laminated Chilean radiata pine and maintains a vertical rhythm every meter with 500 mm x 90 mm slats that integrate LED lighting. Depending on the orientation and technical requirements of each façade, the space between the slats is appropriately filled in (it is left open on non-sunny façades, a frame of 250 mm x 60 mm slats is incorporated on sunny façades and oriented appropriately, and a translucent panel is incorporated on façades where acoustic protection is required). A continuous concrete strip marks where the wood begins on the boulevard and acts as a finishing touch.

Sustainability, circularity and local economy

The club's typology and interests made it possible for manufacturers of steel, plastic, wood, and energy to become strategic partners in the design process. This allowed for the discussion of sustainability strategies across the board, overcoming design limitations and transcending certification frameworks. The main actions can be grouped using the three Rs as follows:

-Reduce construction costs by designing as efficiently as possible. The floor and roof areas were minimized. Instead of a circular design, a rectangular design with smaller square footage was chosen.

-Energy consumption was reduced through the use of efficient air conditioning and insulation systems, high-performance glass, and a double wooden facade for solar control.

-Water consumption can be reduced by recycling gray water and installing an artificial turf field with a drainage and water collection system.

-Use green energy and reduce electricity consumption with LED lighting technology and photovoltaic energy production in the stadium.

-Reuse almost the entire concrete structure of the existing stadium to optimize the new building's carbon footprint.

-Recycle materials from demolition. The steel recovered from the metal roof of the 1988 building was recycled at the plant and used in the new construction. The plastic from the seats was also recycled and molded into new ones.

Additionally, 1,600 cubic meters of Chilean pine laminated wood was used, which spurred significant local industrial development. This development made it possible to supply the necessary volume of structural material and paved the way for the construction of large-span wooden buildings in Chile. This effort captured at least 1,500 tons of CO2.